& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Healthy ocean biodiversity is inextricably linked to human flourishing. Oceans are major carbon and heat sinks for the Earth’s biosphere and provide many millions of jobs globally, as well as food security. More than 50% of the population in the world’s least developed countries is dependent on ocean-sourced food as their primary source of protein, according to the United Nations’ Sustainable Development Goals.

However, since the 1970s, the number of overfished ocean fisheries has tripled, with more than one-third of the world’s assessed stocks now fished beyond biological sustainability, according to a Food and Agriculture Organization of the United Nations 2022 report (p. xix).

Austrian start-up Revo Foods created its high-volume 3D food printer to bring sustainable plant-based seafood alternatives to a wider range of consumers, supporting its larger goal of helping save oceans from ongoing overfishing and other environmental harms.

“We need to provide better alternatives for people who enjoy the taste of fish but don’t like the oceans being destroyed—products that give you the nutritional value of fish, but without the negative consequences,” says Revo Foods CEO Robin Simsa.

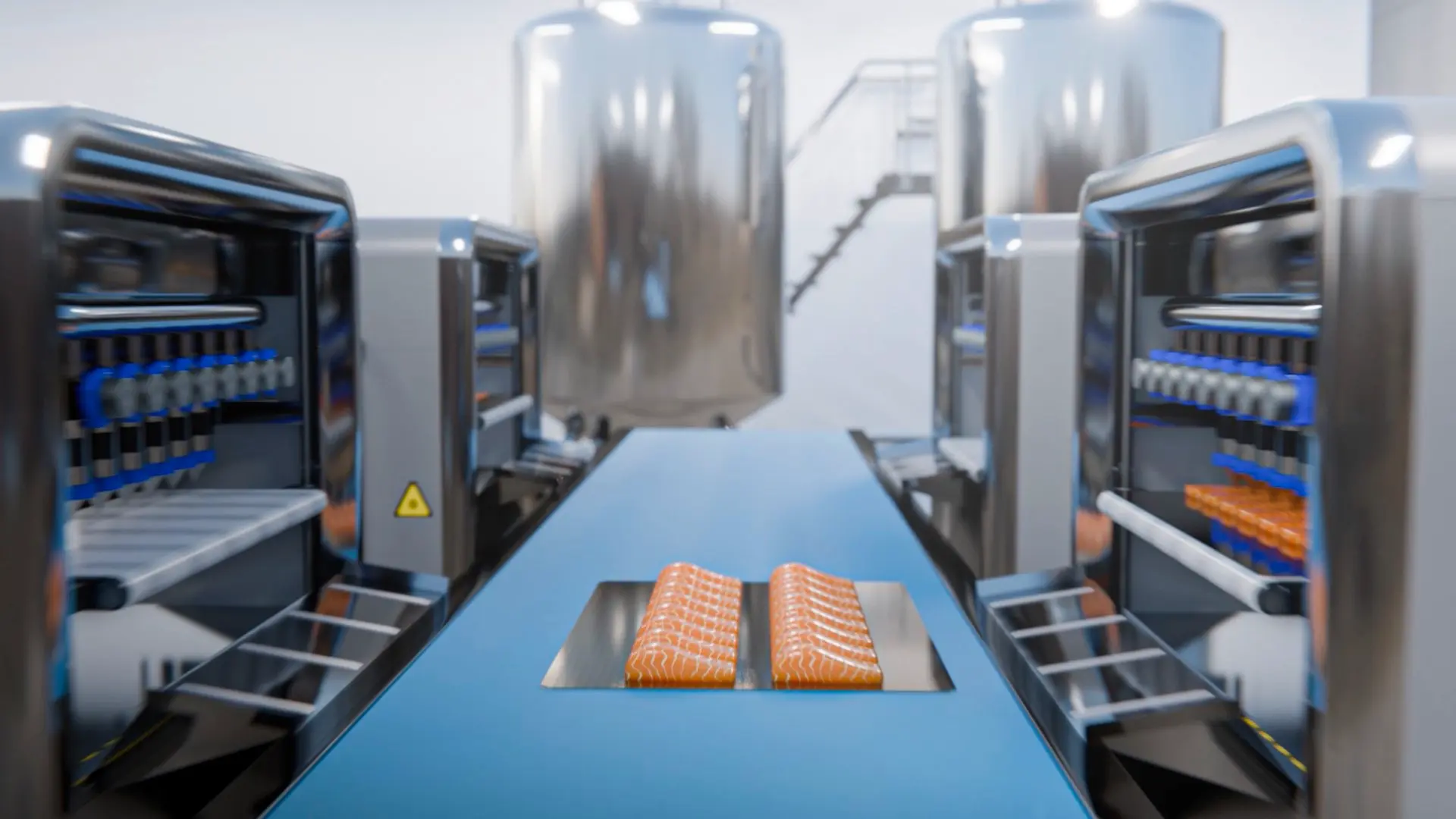

In September 2023, the company launched The Filet, a salmon-inspired mycoprotein product, followed this year by The Kraken, which resembles octopus tentacles in smell, taste, and texture. Both products are available throughout Europe. Revo Foods plans to scale up operations over the next two years to mass-produce 3D-printed food products.

“People always thought of additive manufacturing as a type of prototyping, but not really intended for industrial use,” Simsa says. “Ours is meant as a production system. We were the first company in the world to bring a product made with this type of 3D production system to supermarkets. So there’s been quite a few advances in this technology.”

While technically a food company, Revo Foods is motivated by a larger aim of protecting the biodiversity of the oceans. The company’s products are also free of the toxins—such as microplastics—that can show up in some ocean fishery products.

With overfishing, “we risk losing a huge part of the biodiversity in the oceans,” Simsa says. “We’re dependent on the oceans for our own survival, and it would also be a huge loss for future generations.”

Adding to the sustainability profile of its products, Revo Foods uses mycoprotein, a type of protein derived from fungi that, according to the company, produces 77–86% fewer CO2 emissions and uses 95% less freshwater in production than conventional salmon. The carbon footprint of mycoprotein is 1.5 kg CO2/kg, as compared to 15 kg CO2/kg for salmon and 31 kg CO2/kg for beef. Mycoprotein also has a smaller water footprint—about 500 L per kilogram—than animal proteins.

In addition, “mycoprotein does not require extra processing steps compared with soy or pea protein,” Simsa says, explaining that the processing involves lower temperatures, which preserve vitamins and omega-3 fatty acids. “So there is quite an advantage of using it in our process, in terms of nutrition.”

To help achieve its mission, Revo Foods developed the Food Fabricator X1, a 3D food printer that the company used to bring its initial products to supermarkets. The Food Fabricator X2, which Simsa says is “much faster and much improved,” should be ready this summer.

The new Food Fabricator X2 has a novel multi-nozzle system that allows for continuous food production, a distinct advantage for high volumes. “If we combine additive manufacturing with this multi-nozzle approach to have a larger output at a time, then we’re quickly getting to volumes that are very respectable for a full production system,” Simsa says.

Also included in the 3D food printer is a high-precision extrusion system that supports combining ingredients in any predefined structure, enabling products with customized shapes, structures, and textures without the need for major hardware adjustments during printing.

“It’s the first time that you can create this variability in the product’s appearance, composition, or texture with only a software change,” Simsa says. This also provides “more freedom for product designers and product developers—and also for marketing teams—to bring out a similar offering or a completely new offering.”

Currently, this versatility applies only to foods using the same ingredients, but Simsa says it opens the potential for producing large volumes of products with subtle variations, unlike current mass-production methods that only produce identical products.

“We think that the biggest impact can be achieved if it’s a large volume production system,” Simsa says, “where you can reach as many people as possible, which means retail and big distributors.”

In developing the Food Fabricator X2, Revo Foods was creating a whole new system, not building with “some off-the-shelf equipment” or basing it on someone else’s blueprints, Simsa says. “We had industrial designers, mechanical engineers, and electrical engineers design and test the new machinery.”

To assist in this process, the company’s teams used Autodesk Fusion software “as our design software for many of the hardware components of the Food Fabricator X2,” he says. “We needed to design and make cut files for a bunch of new hardware components, and then test them. Fusion was very useful for this.”

This kind of rapid prototyping, made possible by software advances and additive manufacturing, is especially useful for start-ups that don’t have the resources of a large corporation. “A company like ours couldn’t have existed 20 years ago,” Simsa says.

Fusion also sped up workflow processes. “Before, you needed to send a design to a specialist company, and the component would come back two weeks later, but maybe the design didn’t fit, so you would need to do it all over again,” Simsa says. “But now we can iterate almost on a daily basis. People have an idea in the morning, design it, and then 3D print it and test it that day.”

Adding to Simsa’s point about modern start-ups, crowd investing also did not exist 20 years ago. However, today, start-ups can gain vital funding through campaigns on crowd-investment sites, like the one that Revo Foods is using to raise money, German-based green-tech investment platform Funder Nation. With crowdfunding support, Revo Foods plans to scale up its production capacity throughout 2024 and 2025, so it can make an even bigger impact on a sustainable food supply.

Shawn Radcliffe is an Ontario, Canada–based freelance journalist and yoga teacher, specializing in writing stories about health, medicine, science, architecture, engineering, and construction, as well as yoga and meditation. Reach him at ShawnRadcliffe.com.

PD&M

Image courtesy of Batch.Works.

Emerging Tech

D&M