& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

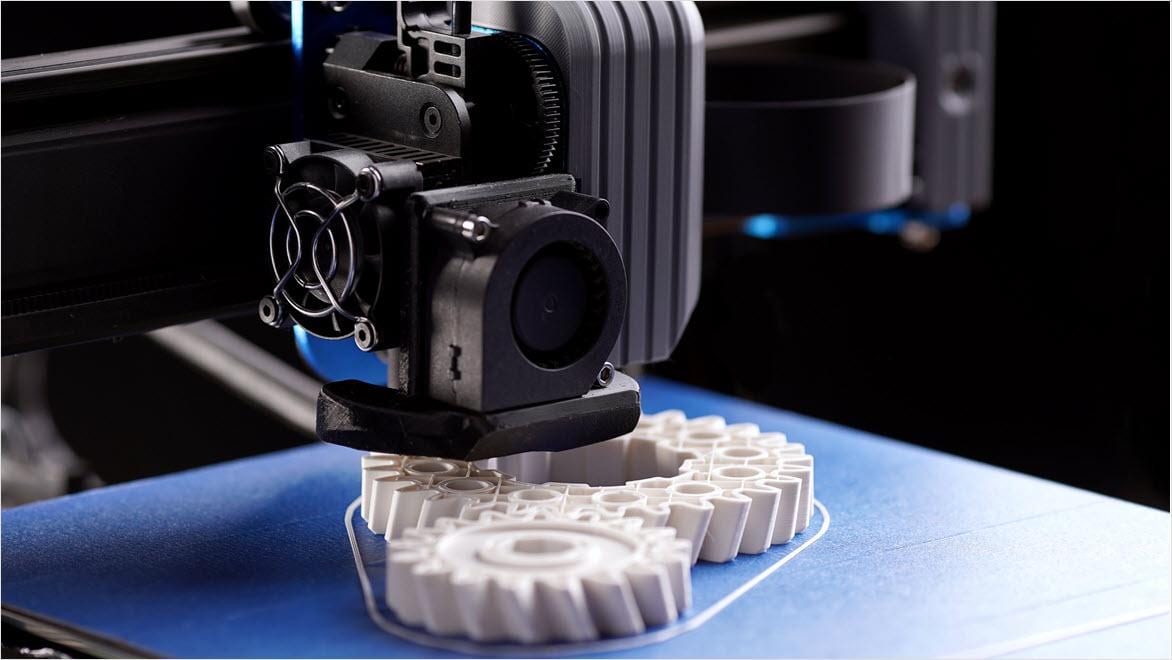

3D printing, also known as additive manufacturing, is a process that involves creating a physical 3D object from a 3D CAD model, or other physical file. 3D printing is an additive process where layers of material are built up to create a tangible 3 dimensional object.

3D printing software is a computer program used to prepare and convert 3D models for 3D printing. This software is to create or modify 3 dimensional designs and convert them into a format that a 3D printer can understand and use.

3D printing software like Autodesk Fusion is a critical tool for preparing 3D models for printing. The process starts with creating or modifying a 3D model using Fusion's advanced features. After finalizing the design, the software slices the model into horizontal layers, creating a file that guides the 3D printer in constructing the object layer-by-layer.

Additionally, Fusion supports a variety of materials for 3D printing, including plastics like PLA and ABS, metals, ceramics, and even wood composites. The choice of material can influence the final object's properties, such as its strength and appearance. This versatility, combined with Fusion's capabilities, enables a wide range of 3D printing applications.

3D printing using Fusion is as easy as it gets.

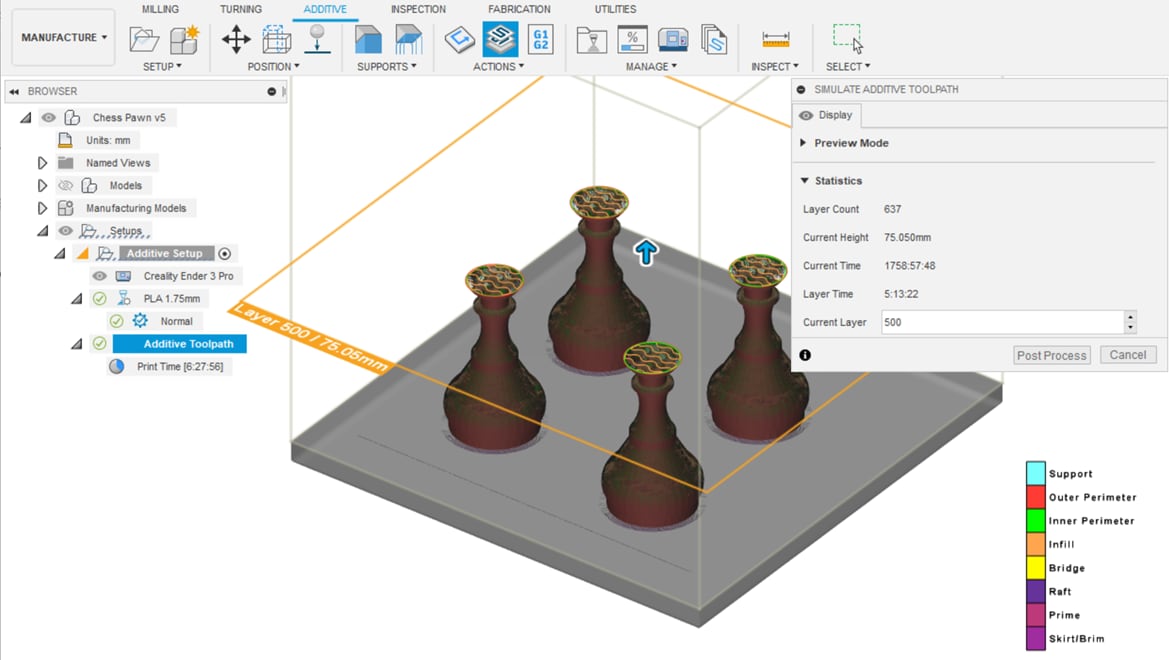

Fusion has the tools to automatically orient and arrange your parts within your 3D printer's build volume. If necessary, Fusion can also generate support structures. Once your setup is finished, you can slice your models, and connect to your printer to start the printing process.

3D printing, enabled by software like Autodesk Fusion, serves various applications in both personal and professional settings. For personal uses, it's utilized for crafting custom items and educational models. Professionally, it's used in healthcare for tailored prosthetics, in automotive and aerospace for prototypes and lightweight structures, and in architecture for building models and components. Fusion enhances these processes by streamlining design, collaboration, and fabrication workflows.

Learn about the different types of 3D printing applications

3D printing is used to quickly create rapid prototypes for visual aids, assembly mockups, and presentation models.

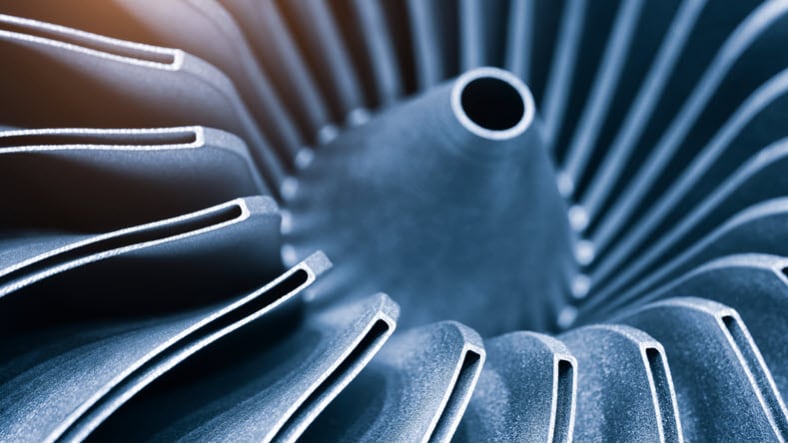

Fuel efficiency and emissions reductions are driving the need for lightweight parts with 3D printing in aerospace and automotive applications.

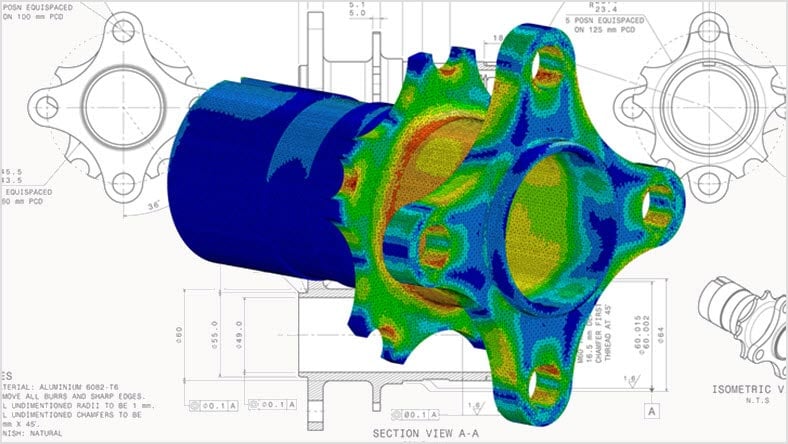

3D printing removes many of the constraints imposed by traditional manufacturing processes that prevent engineers from truly designing for optimal performance.

Dr. Hannes Schwenke uses 3D printing to produce accurate models of patient organs to treat them more effectively.

Fuel efficiency and emissions reductions are driving the need for lightweight parts with 3D printing in aerospace and automotive applications.

Habitat for Humanity and PERI 3D Construction built the organization’s first 3D-printed home, reimagining what affordable housing may look like.

3D printing has a number of benefits from prototyping to cost & material optimizations.

3D printing allows for the creation of highly complex and intricate designs that are challenging or impossible to achieve with traditional manufacturing methods.

3D printing accelerates the product development process by enabling quick and cost-effective prototyping. Design iterations can be rapidly produced and tested, reducing the time and cost associated with traditional prototyping methods.

3D printing can be cost-effective for low-volume or customized production. It eliminates the need for expensive molds, tooling, and setup costs associated with traditional manufacturing methods.

Traditional subtractive manufacturing processes often generate significant material waste, as excess material is removed during machining. 3D printing is an additive process, where material is added layer by layer, resulting in minimal waste generation.

Autodesk's tools like Fusion, simplify 3D printing. They offer easy model creation, advanced capabilities, and a preview for pre-print perfection. Ideal for all users!

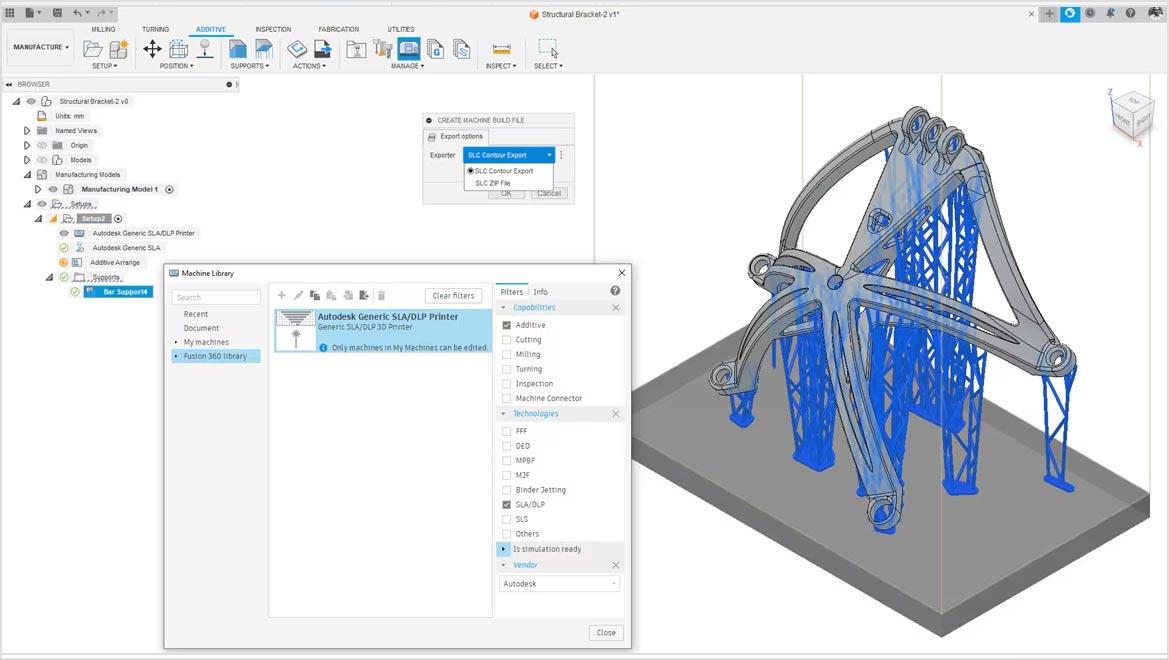

Autodesk expertly auto-creates support structures for 3D printing intricate models. These supports ensure stability, uphold weighty parts, and allow easy post-print removal, ensuring a neat, precise result.

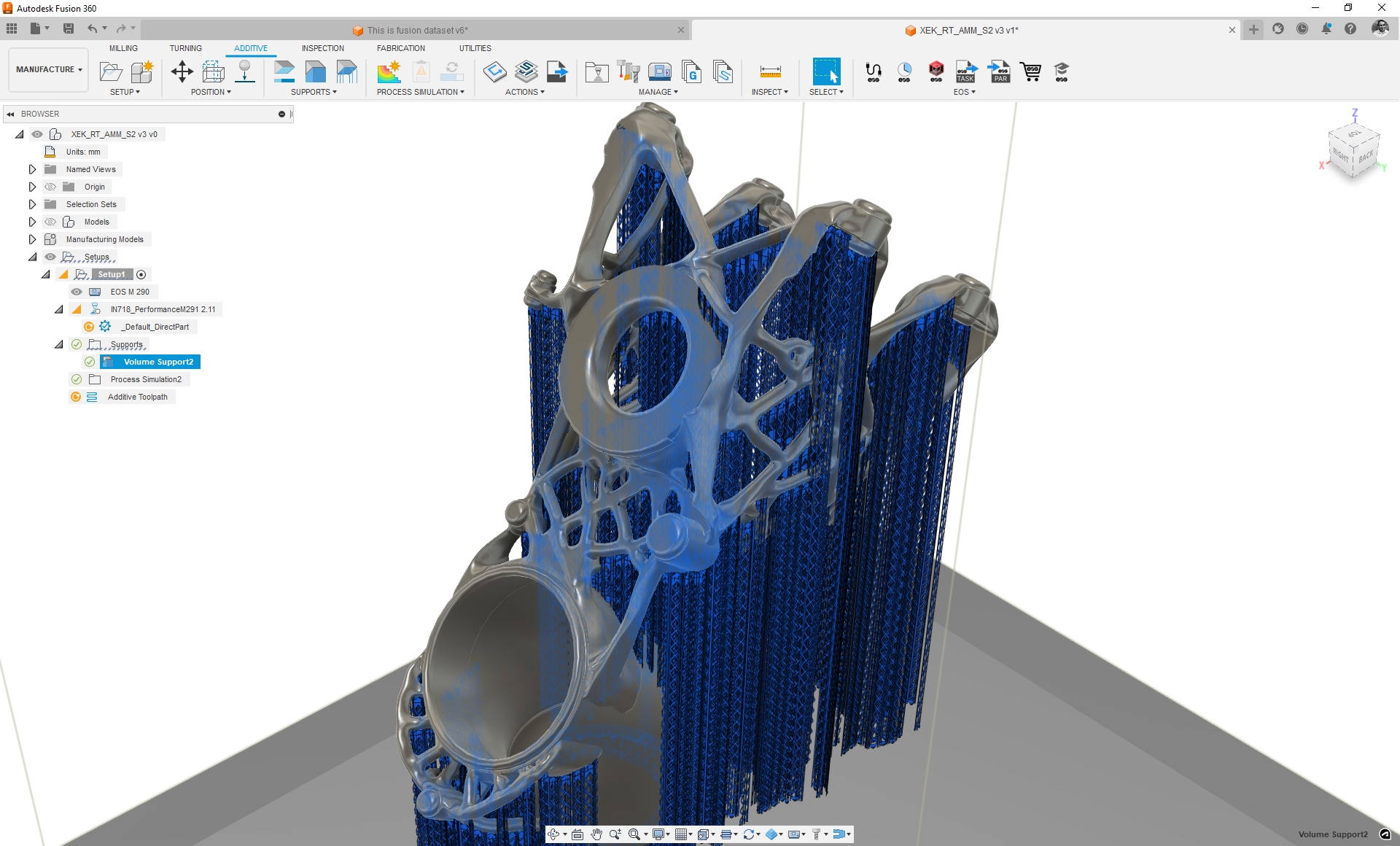

Autodesk optimizes 3D printing by checking models for issues and providing rectification tools. This preparation phase refines geometry for best outcomes, turning designs into high-quality objects.

The Fusion Manufacturing Extension allows you to quickly create subtractive finishing operations and machine precise features with high-quality surface finishes.

Learn the best way to use your 3D printer with Autodesk 3D printing software tutorials.

Learn how to prepare models for additive manufacturing using additive FFF (fused filament fabrication) and SLA (stereolithography) technologies.

Learn how to prepare parts for additive manufacturing using MPBF (metal powder bed fusion) machines using the Fusion Manufacturing Build Extension.

Explore free 3D printing resources & learn how to make the most of 3D printing with Autodesk software.

Explore this comprehensive guide to grasp 3D printing and 3D modeling basics. Learn about crucial terminology, different types of 3D printers, and discover how Fusion can significantly enhance your projects.

3D printing and additive manufacturing may be synonymous terms at the surface level, but as the industry grows, additive manufacturing becomes more of an all-enveloping term.

Autodesk Fusion, makes 3D printing easy by providing an integrated CAD/CAM environment, an additive manufacturing extension, helpful add-ins, and more.

The future of 3D printing is promising with advancements in speed, material quality, and manufacturing capabilities. These improvements aim to enhance accessibility and productivity while reducing costs, revolutionizing various industries.

3D printing has transformed industries with on-demand part production, personal creativity enhancement, and swift prototype development. Its affordability and flexibility have ushered in new manufacturing and design opportunities.

Beyond plastic, 3D printing is expanding to include materials like metal, wood, and even concrete, paving the way for faster, more sustainable, and cost-effective manufacturing in industries from automotive to construction.

Learn more about 3D printing software with these top questions frequently asked by users.

3D printing is a rapid prototyping process, mass customizable manufacturing process, and a technology that enables the creation of complex geometries previously not possible through other manufacturing processes. It’s also a digital manufacturing technology that requires no tooling changes for revised parts, which means there’s no downtime between product revisions or manufacturing entirely new products.

Yes, Autodesk Fusion, has a dedicated additive manufacturing space, marrying design, engineering, simulation, and manufacturing all together.

3D printing a part is a combination of the material that you wish to use and the volume. Because 3D printing can output using a plethora of plastics and metals, the cost of a part can vary dramatically depending on what you are using. However, it can be more affordable per part than other processes.

Autodesk Fusion is an excellent choice for creating CAD models for 3D printing. It allows you to create not only “prismatic” models such as gears or brackets, but it also allows you create more “organic” models using T-Splines, including characters, plants, and vehicles. You can use Fusion to create and then edit your objects for 3D printing. Bring in models from other software and make modifications, such as de-featuring them by removing small features or blends. Fusion can export as an OBJ or STL file format that is read by most 3D printing software. It also has the ability to print directly to your 3D printer. In addition, Fusion even allows you to edit mesh or STL data that is brought in from a laser-scan or other source. Before printing, you can reduce or increase the surface count, edit out features, fill holes, etc.

CAD 3D printing software allows you to conceptualize, design, and optimize your models for fitting production technologies.

Autodesk Fusion can be used with any 3D printer. It provides a wide range of printer and material profiles, and it exports models in STL format, which is compatible with most 3D printers.

Yes, 3D printing software can significantly improve the quality of your prints. The software allows for precise control over many variables in the printing process, such as layer thickness, print speed, and infill density. It can also help you identify and fix potential problems in your design before printing, reducing the risk of print failures. Advanced software like Autodesk Fusion even offers simulation tools, which can predict how the print will behave under various conditions, helping you optimize your design for the best possible print quality.

Yes, Autodesk's 3D printing software can be used on any computer, provided it meets the system requirements. For instance, Autodesk 3Ds Max is only available in a Windows version but it can be run on a Mac using Boot Camp. Fusion has a complete workflow for 3D printing, including modeling and slicing, and is focused on usability which makes it accessible for users of different skill levels.