Keyboard ALT + g to toggle grid overlay

Manufacturing technology can streamline construction to address urgent health-care capacity needs

In a time when the nation’s inventory of health-care facilities is stretched to its limit by the COVID-19 crisis, Alabama-based BLOX is industrializing the complex task of hospital construction. The company uses manufacturing technologies to rapidly build acute-care medical facilities in states throughout the US—by fabricating building components in a factory, shipping them to the jobsite, and assembling them in place. With a flexible, integrated cycle of design, manufacture, and construct, BLOX’s approach to modular hospital construction serves as a model for adding capacity to a stressed health-care system.

The efficiency gap in construction

In 2000, Chris Giattina was the principal architect of GA Studio, hired by a Japanese automaker to design and construct an employee training facility in Alabama in just nine months. Six weeks from the initial meeting, the company broke ground—and the project was delivered on time with the automaker providing the resources needed. It was a revelation for Giattina, who noted the wide gap between the efficiencies of the automotive industry and the change-resistant American construction industry.

In 2010, that aha moment led to the birth of BLOX, an Alabama-based design, manufacturing, and construction company that’s using modular design to modernize old-school building practices. Giattina, now president of GA Studio and CEO of BLOX, leads the BLOX team in designing and building health-care facilities from the ground up, in a fraction of the time traditional construction takes without compromise to cost or quality.

Applying modular thinking to hospital construction

“We focused on health care because there was a pressing need to figure out how to get good product to market in a tight labor market,” Giattina says. With an aim to deliver building projects with double the quality, speed, and value of traditional methods, the first step was standardization.

BLOX started out prefabricating smaller standard components such as ceiling racks, surgical racks, hospital headwalls with electrical and medical gas systems, and bathroom modules complete with plumbing. “We first learned how to make small, complicated things and then graduated to making small buildings,” Giattina says. “Consider a Russian nested doll: We’re making a small piece that fits into a bigger piece, which fits into a bigger piece, and ultimately fits into what we call an uber module, which is the largest thing that you can ship on a highway.” An uber module—15 feet wide, 15 feet tall, and 60 feet long—can comprise an entire trauma center, or a set of rooms such as labs, imaging rooms, patient rooms, and even break rooms.

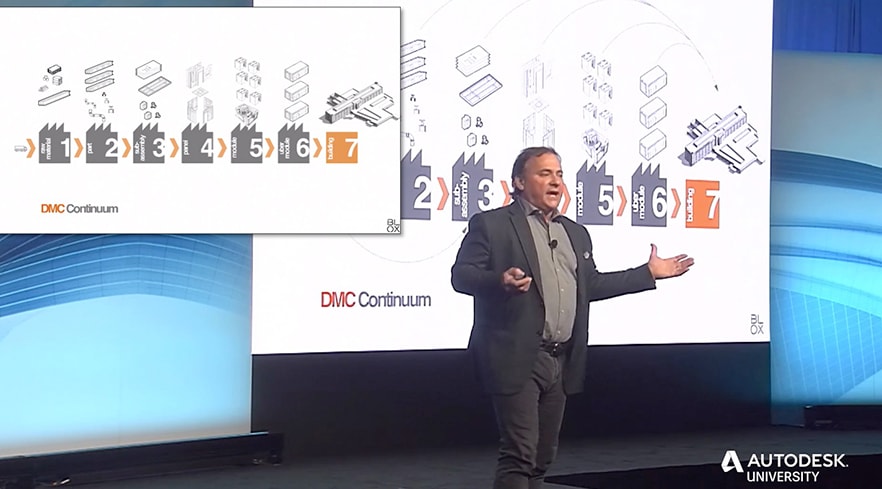

BLOX CEO Chris Giattina describes the DMC continuum at Autodesk University 2019.

The Design-Manufacture-Construct continuum

The BLOX team uses a building delivery system Giattina calls Design Manufacture Construct (DMC). “If you think about a continuum, then there’s really raw material at one end and it gets processed in incremental steps until it becomes a building,” he says.

On the DMC continuum, a building can consist of any combination of standard components, subassemblies, panels, modules, and uber modules. Components are designed and fabricated in the controlled factory environment of the BLOX manufacturing facility (formerly a railcar plant) in Bessemer, AL, using repeatable processes and systems. “In a case where we have fewer and fewer skilled laborers, we’re creating systems that allow unskilled labor to do things that used to require skill,” Giattina says. “The skilled people shift to become the machine-makers,” creating processes and tools that can be used by other workers.

Modular mitigates construction risk

The actual hospital construction site then becomes an assembly site instead of a higher-risk conglomeration of various trades creating a custom build on-site. “At the jobsite, the foundations come in, and then you put these big boxes on them—there may be 20 or 50 that go to a site,” Giattina says. “Frame between them with a kit of parts that might be flat packed, and then place together walls that are already made in a factory.”

Some of the BLOX team’s recent projects include free-standing emergency departments in Nevada, Florida, and Texas for Universal Health Services (UHS); standard modules for acute-care patient rooms in dozens of hospitals for HCA Healthcare; and currently underway, a 170-bed hospital in Nevada. By streamlining the construction lifecycle, moving directly from design into fabrication, Giattina says, “You can make a whole building in about three weeks and just keep them coming.”

Designing a digital workflow

Software and data analytics have been the key to developing a DMC operation. BLOX is a longtime user of Revit to design its building components. The next step was to integrate the digital designs with the manufacturing process on the factory floor, via a cloud-based data-management system. “We’re going from model to fabrication, and we’re doing it systematically,” Giattina says. “We’ve developed a platform called WEVR that uses our own software development with Forge and BIM 360.”

The WEVR platform mines the data from myriad state health-care regulations and input on clinical practices from health-care facility staff and management to identify hundreds of design possibilities. An algorithm reduced the design possibilities down to a few standard ones that meet multiple states’ rigorous requirements. “At that point you can manufacture a part that can be used in Reno, Nevada, or in Miami, Florida,” he says. “Essentially we’re taking an industrialized process and a data-driven process to come up with best-in-class solutions for components that can be assembled in hundreds, if not infinite, numbers of ways” into health-care facilities.

Using modular hospital construction to address the COVID-19 crisis

Today, in the midst of the ongoing coronavirus health-care crisis, the BLOX plant is in full production with its ongoing hospital projects. But the company has also laid plans to use its industrialized construction process to address one of the most urgent health-care priorities for cities and states all over the US: the need for more hospital beds to treat patients suffering from COVID-19. The company is adapting its systems to build institutional-grade mobile isolation care units (MICUs) that can be rapidly deployed to the areas that need them most.

The company has developed a design for a 16-bed MICU ward that can be manufactured as modular units at the plant, transported by truck, assembled on-site, and ready for patients a week later. According to Giattina, the first MICU could roll off the production line in just four weeks. BLOX expects to be able to rapidly scale capacity to produce 250 beds per month at its factory, and 10 times that amount through supply-chain partnerships nationwide.

A model for addressing the health-care facility shortage

The BLOX MICU would allow medical providers to quarantine patients with COVID-19, preserve the capacity of existing hospitals for other patients, and protect frontline workers from unnecessary exposure. And with COVID-19 hot spots cropping up in areas both urban and rural, “the first MICUs could be in any of the spots that are needed,” Giattina says. “They can go just as easily to one or the other” because the artificial-intelligence (AI) technology and data analytics that power the DMC platform accommodate different states’ regulatory requirements for hospital facilities.

The company’s DMC delivery system has helped BLOX take an agile approach to this once-in-a-generation challenge. “We’ve built a team of insanely smart people: 400 architects, engineers, programmers, manufacturers, contractors,” he says. “And we’re all working to solve the very, very hard problems and make our industry better.”