& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Design for manufacturing (DFM) is the process of designing a product with the goal of making it easier, more cost-effective, and more efficient to manufacture. DFM involves considering the manufacturing process, materials, and tools required. And then analyzing the design for potential issues that could arise during manufacturing. Optimizing manufacturing involves reducing production time, and reducing production costs while minimizing the risk of known issues or errors.

By addressing issues early in the design process, designers, engineers, and manufacturers can avoid costly and time-consuming delays or redesigns. Thus making sure that the process is efficient and produces a product that is high quality and cost-effective to manufacture.

Simplify the design where possible by reducing the number of parts, components, and complex features.

Choose materials that are easy to source, cost-effective, and suitable for the intended purpose to avoid increasing production costs.

Use standard components and fasteners were possible to reduce the need for custom manufacturing processes or special tooling.

Design components with correct tolerances to determine proper fit and alignment during assembly to keep manufacturing costs lower.

Use prototyping and testing to validate the design prior to production to identify and correct issues early-on in the process.

Select manufacturing processes that are suited to the design. Consider factors such as machining, 3D printing, and injection modeling to help minimize waste.

By facilitating side-by-side comparison of multiple design iterations, configurations enables data-driven decision-making, reduces prototyping and manufacturing time, and offers a seamless transition from design to CAM workflows. Reducing the need for re-calculating or applying new toolpaths and accelerating time-to-market.

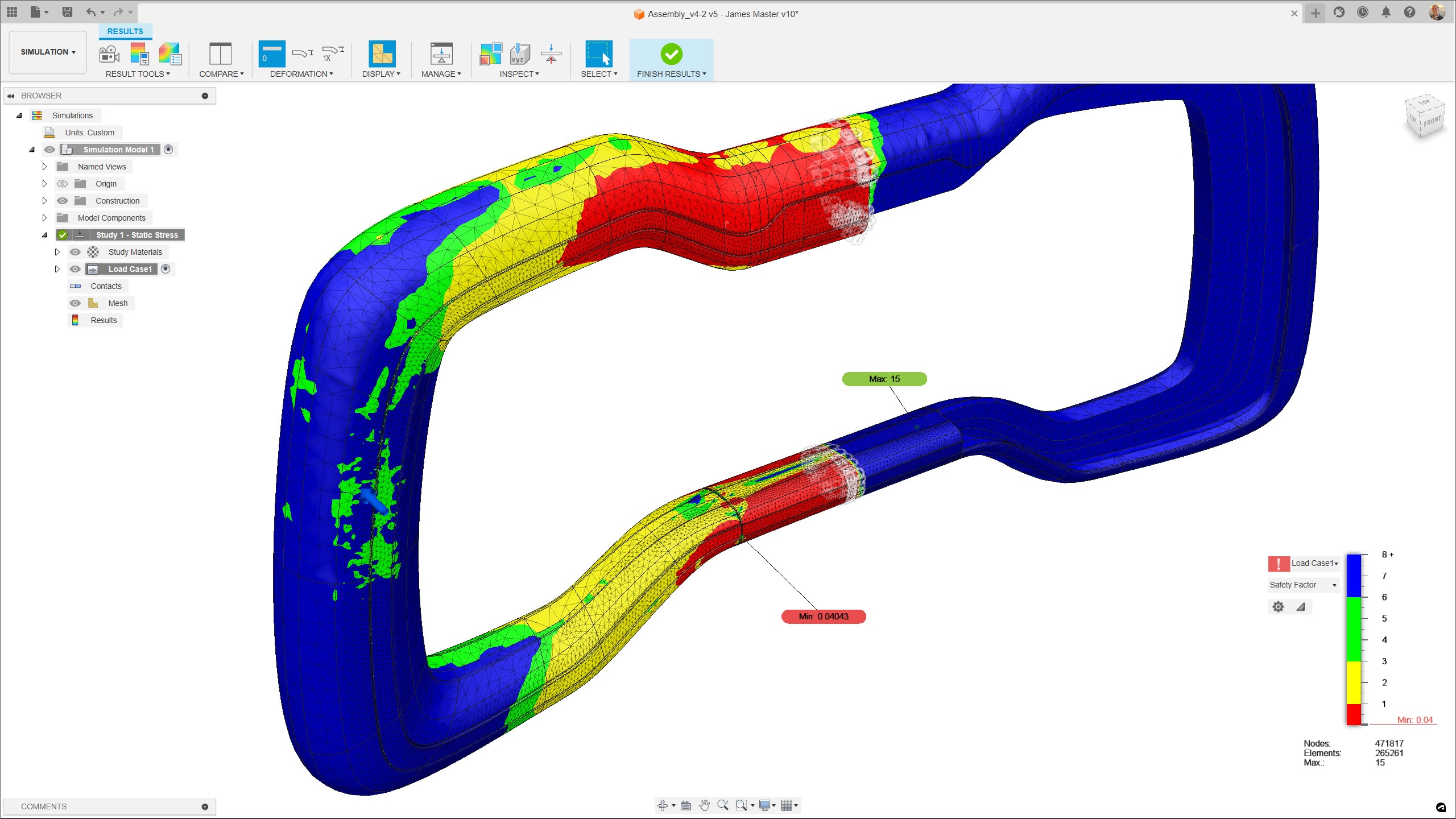

The simulation tools in Autodesk Fusion allow you to optimize the design before it is manufactured. This leads to lower costs, improved performance, and reduced environmental impact.

Dispersed manufacturing teams use Autodesk Fusion to efficiently ideate, create, collaborate, and manage their development processes in a single solution with cloud and data at the center.

Autodesk Fusion offers fully integrated ECAD and MCAD giving you the ability to create the next generation of products with a unified schematic, PCB, library management, simulation, and mechanical design on a single platform

Autodesk Fusion makes it easy to document your designs with 2D drawings, including dimensions, notes, tolerances, custom properties and more.

Design for manufacturing software helps identify manufacturing issues upfront, helping to eliminate costly design changes and production delays.

DFM helps in designing products that are easier to manufacture, more reliable, and higher quality leading to less issues and increased customer satisfaction.

Design for manufacturing software speeds up the product development process, allowing companies to bring products to market faster when compared to the competition.

DFM software makes collaboration between designers, engineers, and other stakeholders much easier leading to more innovative product development.

DFM software helps to optimize material usage and reduce waste, leading to environmental benefits and cost savings.

Design for manufacturing software helps improve production efficiency by using all available manufacturing processes, resulting in reduced lead times and increased throughput.

Companies that use DFM software effectively can provide cost-effective products with improved quality and faster delivery times, making them more competitive in the market.

DFM software helps support sustainable design practices by optimizing material usage, reducing energy consumption, and minimizing waste.

Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Design for manufacturing (DFM) software is used in a wide range of industries where product design and manufacturing processes are integral to their operations. Here are some industries that extensively use DFM software.

The automotive industry uses DFM software to optimize the design and manufacture of vehicles and their various components. Thus reducing production costs, improving vehicle performance, and enhancing safety.

DFM software is important for the aerospace industry when designing complex aircraft. It makes sure that these products are not only efficient but also meet strict safety and performance standards.

DFM software is a necessity in the medical device industry to design and manufacture precision equipment and devices. It aids in compliance with strict regulatory standards and enhances the manufacturability of medical devices.

Electronics manufacturers use DFM tools to design circuit boards, casings, and other components. It helps in minimizing material waste, improving product reliability, and reducing production costs.

Visualize design for manufacturing issues, save time ordering parts, and get instant pricing and lead times with the Xometry add-in for Autodesk Fusion.

Learn about the significance of design for manufacturability and how Autodesk Fusion contributes to streamlining the design-to-production journey.

Learn about the top ten design for manufacturing mistakes now, so you don't make them in the future.

Design for manufacturing (DFM) is an approach used in product development to optimize the design of a product or component. The goal is to make it easier, more cost-effective, and more efficient to manufacture. The primary objective of DFM is to make sure that the final design can be produced with minimal waste, reduced production time, and lower production costs. While ultimately still meeting all the functional and quality requirements of the product.

Design for manufacturing (DFM) software is a type of computer-aided design (CAD) software that helps engineers and designers optimize product designs for efficient and cost-effective manufacturing. It provides a range of features and capabilities aimed at identifying potential manufacturing issues, improving product manufacturability, and streamlining the product development process. Get started with a free 30-day trial of Autodesk Fusion today.

Design for manufacturing is important because it aligns the design and manufacturing processes. It leads to cost savings, improved quality, faster time to market, and other benefits that are crucial for the success of a product and company.

Autodesk Fusion allows engineers to consider manufacturing processes, materials, and constraints during the design phase to make sure that the final product can be produced efficiently and more cost-effectively. Get started with a free 30-day trial download here.

Manufacturing companies can benefit in many ways by using DFM software. Some of which include: