& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

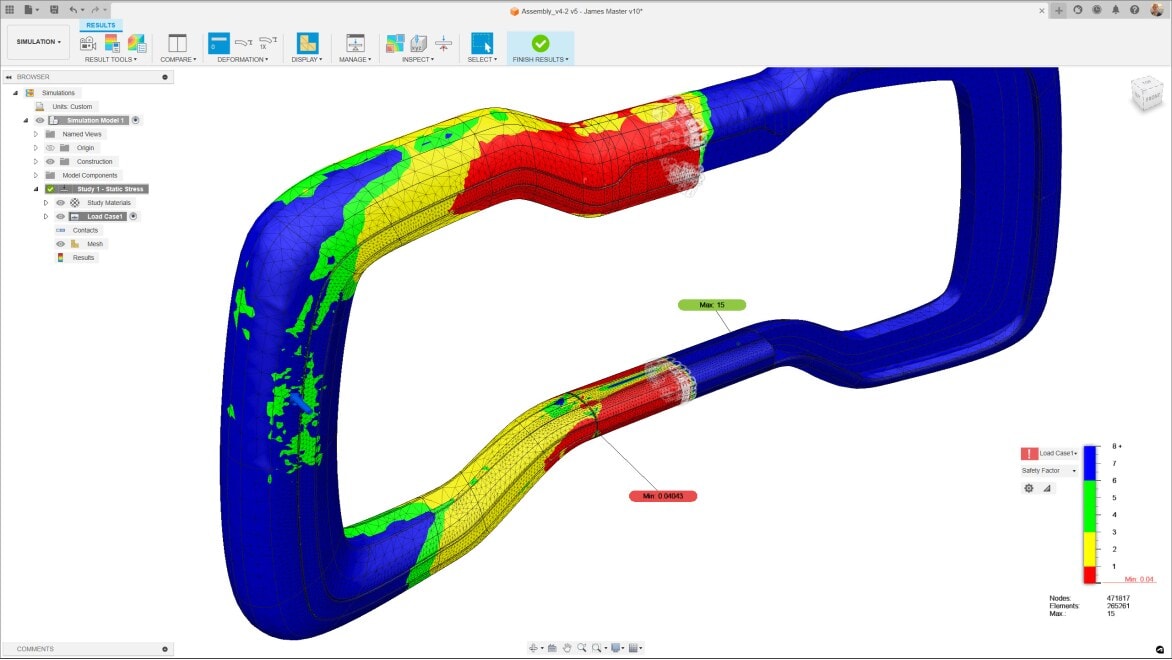

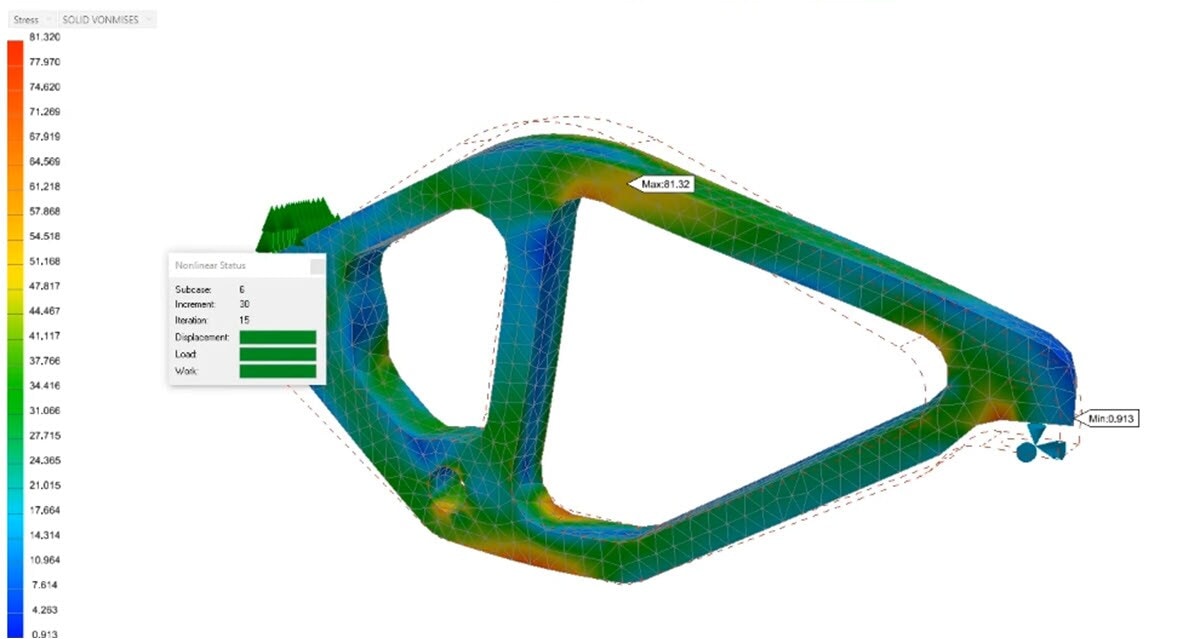

Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Finite element analysis shows whether a product will break, wear out, or work the way it was designed. In the product development process, FEA simulation is used to predict what is going to happen when the product is used in its real world application to ensure it achieves whatever tasks that component needs to perform safely and efficiently.

Finite element analysis (FEA) software works by breaking down a real object into a large number (thousands to millions) of finite elements in the forms of shapes like cubes or tetrahedrons. Mathematical equations help predict the behavior of each element. A computer then adds up or averages all the individual behaviors to predict the behavior of the actual object.

Finite element analysis helps predict the behavior of products affected by many physical effects, including:

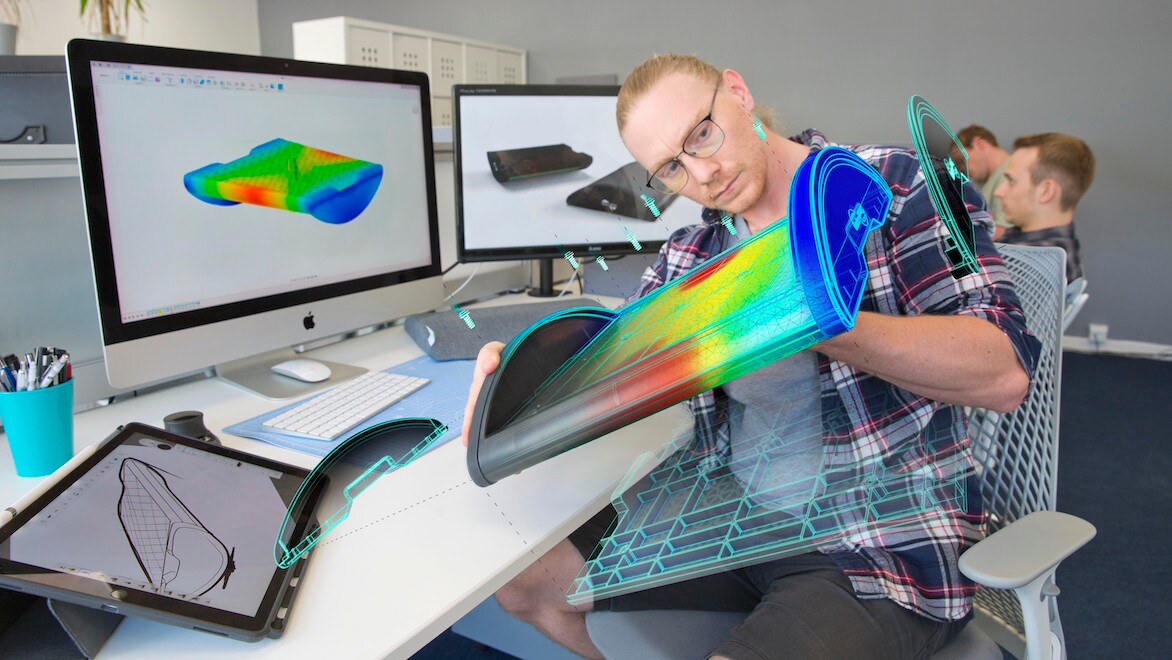

Finite element analysis (FEA) software closes the gap between your 3D design and the real world. When you can apply forces like heat, mechanical stress, and vibration computationally to your digital model, its performance in the real world can be modeled with a deep level of accuracy.

FEA software lets you prototype virtually, addressing each area of lower-than-acceptable performance in turn (or all at once) to improve your model before you ever commit time and resources to making a physical prototype.

In addition, you can pre-load simulations with predictive analysis, introducing historical data about similar objects to give you an even better starting point.

Image courtesy of Dynamic Structures Ltd.

See how the Autodesk solution for FEA and digital prototyping is helping manufacturers design, visualize, and simulate consumer products, industrial machinery, building products, and more.

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

Professional-grade product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

Students can push the boundaries of finite element analysis and simulation with Autodesk software. Download the same, full version software that more than 9 million designers, engineers, and digital artists are using, including Autodesk Inventor Professional, Autodesk CFD, Autodesk Moldflow Advisor Ultimate, and Autodesk Robot Structural Analysis Professional software.

FEA software takes your 3D design file and tests its performance against the fluid dynamics, heat transfer, mechanical stress, and other factors it will be exposed to when it exists in the real world.

Finite element method (FEM) is the solving of equations generated by the mathematical modeling of engineering projects.

Finite element analysis (FEA) is the application of finite element method (FEM) data, which interprets its mathematical values and analyzes how you can improve the performance of your model when exposed to various physical forces.

You absolutely can do FEA by hand. Finite element analysis (FEA) is just math. In the pre-digital age, performance calculations were done on paper using a physical prototype during testing.

The difference today is that the algorithms driving simulation software can perform FEA calculations much faster and can test for multiple force effects simultaneously.

It also means you don’t need to build a physical model to apply calculations—the system can apply them to your 3D design without leaving your desktop.

While FEA by hand is still feasible for simple geometries or when a prototype already exists, FEA simulation software can test the performance of ever-more complicated geometries, so the design process isn’t constrained by what you can measure by hand.

Simulation software is quite workstation intensive. A general rule of thumb is that you need around 16 GB of RAM per million degrees of freedom in a standalone system, but this can vary greatly based on model complexity.

The ability to solve many simulations using secured cloud solving does free up personal system resources such as RAM, however, for the software that also has the ability to solve simulations locally (such as Moldflow and CFD), the installation guides provide test cases to recommended RAM and other resources for the installation to run efficiently. Here is a breakdown for the current releases of Autodesk simulation software:

Inventor Nastran, Autodesk’s dedicated CAD-integrated simulation product, costs as little as