& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Autodesk Fusion connects product development processes end-to-end and integrates a broad array of manufacturing hardware solutions, ultimately improving simulation before manufacturing, and productivity during operations.

Our Machine Tools, Additive Machinery, Tooling, Probing & Work-Holding partners come in all shapes, sizes, and variants. Autodesk’s ever-evolving ecosystem of hardware partners delivers machine integrations and enables deeper integrations through partner add-ins in Autodesk Fusion, like Haas, Mazak, Ultimaker, HP, Dormer Pramet, and Sandvik. See some of our key partnerships below and explore how we are accelerating innovation in manufacturing.

Haas Automation and Autodesk Fusion have partnered to streamline your workflow from CAD/CAM to CNC machining through various in-product integrations, add-ins, and vetted machine and tooling data.

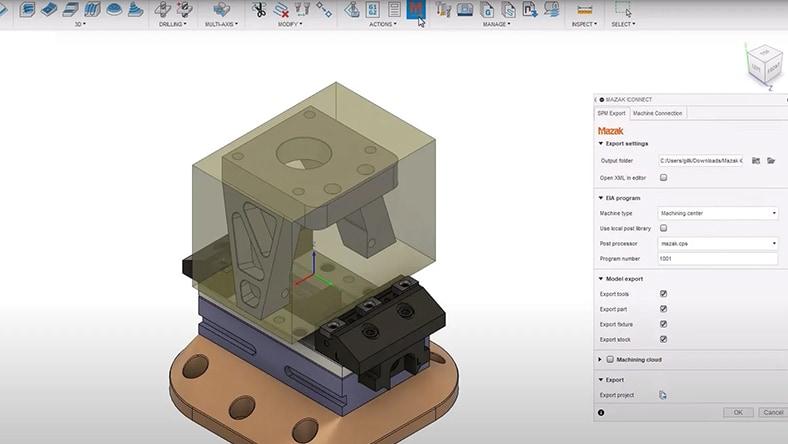

Mazak and Autodesk Fusion have partnered to enable a closer connection between Mazak machines and your CAD/CAM environment. Program, simulate, and transfer data to your machine with greater ease, while minimizing errors.

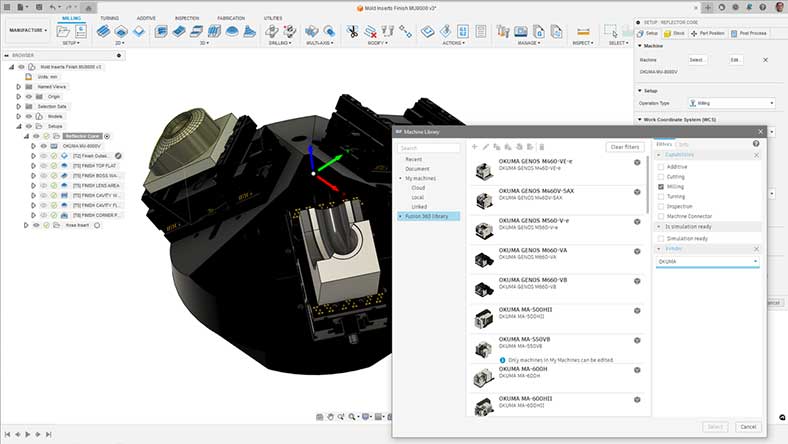

Okuma and Autodesk Fusion have partnered to simplify the process of transitioning from CAD/CAM to your Okuma machine tool. Experience faster and more straightforward programming, simulation, and machine operation, while decreasing the likelihood of errors.

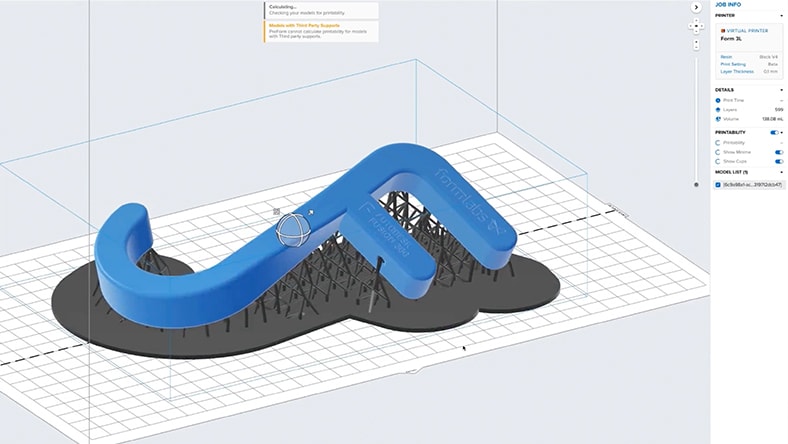

Formlabs and Autodesk Fusion have partnered to streamline the design-to-manufacture workflow. Create your designs, modify them for 3D printing, and orient and pack them in 3D with the build platform for Formlabs SLA or SLS printers.

Sandvik Coromant and Autodesk Fusion have partnered to enable efficiency and process security to the CAM community. Users of CoroPlus Tool Library can get the tool and cutting data recommendations, build tool assemblies and bring their work into Autodesk Fusion in an integrated and intuitive workflow.

CNC machine tool manufacturer collaboration gives you confidence that your machine will be up and running quickly with machine simulation models and dedicated post processors.

Dynamic tool libraries and add-in integrations simplify the tooling selection process of CAM programing with the ability to directly import tooling geometries and cutting data.

Direct import of fixturing and workholding models allow for the creation of accurate manufacturing setups.

Integration of 3D printer machines creates easy access to standard manufacturer parameters for process simulation and build settings.