This post is also available in: Français (French) Italiano (Italian) Deutsch (German) 日本語 (Japanese)

10 ways Fusion 360 supports designers and engineers during the prototyping and fabrication stages of product development.

Prototyping is a fast-paced process, and those who do it every day know that it’s rarely linear. Teams need to investigate as many design and manufacturing options as possible, as quickly as possible, to reach the most ideal go-to-market solution. In doing so, teams and those who wear many hats often jump back and forth between 3D modeling, simulation, electronics – you name it – to iterate and solve inevitable roadblocks before landing on a design that’s just right to send to fabrication.

However, counter to popular belief, prototyping quickly does not mean you have to sacrifice quality. And there’s no need to use different software for each stage of product development (talk about confusing). A single solution that follows you from prototype to fabrication to final product exists; Autodesk Fusion 360.

Fusion 360: professional prototyping and fabrication tools at your fingertips

Fusion 360 connects every stage in the product development process — from prototyping to fabrication. Its robust tools across CAD, CAM, CAE, and PCB enable your team to bring product ideas to life quickly and efficiently. Here are 10 ways Fusion 360 supports designers and engineers during product development:

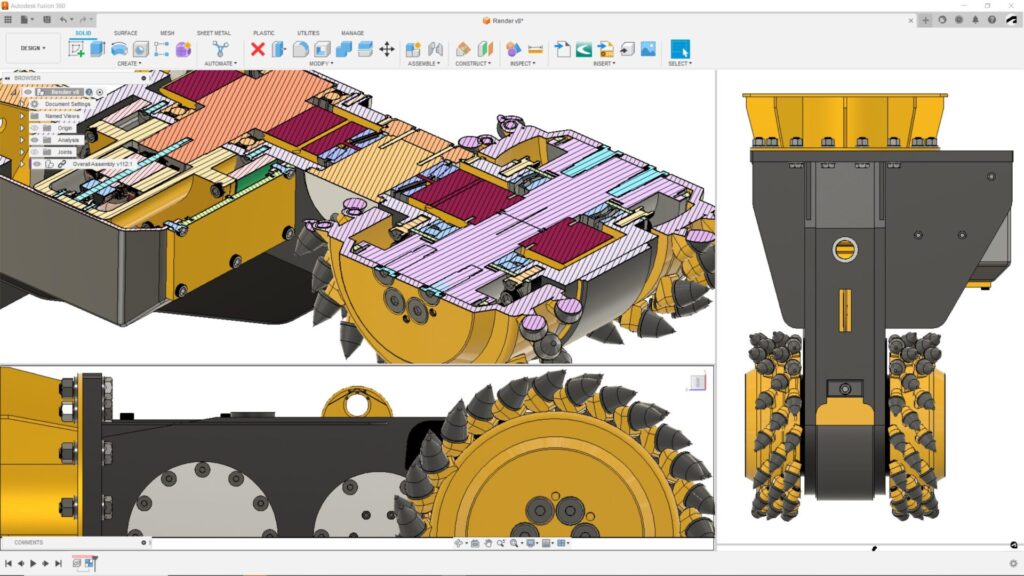

1. 3D model parts and assemblies

The 3D modeling tools in Fusion 360 enable teams to design anything. Fusion 360 offers a wide range of professional-level features to create 3D models, including sketching, surfacing, parametric modeling, freeform modeling, and more. Its intuitive interface has accessible menus and toolbars that make it easy for teams to adopt.

2. Seamlessly collaborate with Assembly Concurrency

Starting a project with effective collaboration sets the stage for successful product development. Gone are the days of outdated, fragmented workflows and time-consuming file exchanges. Assembly Concurrency enables you to seamlessly collaborate with teammates, contractors, or clients in an assembly. And browser access gives easy job site access for those who need to hop into 3D models on the fly. Want to quickly share a model to convey your idea? public link sharing enables you to share models directly with others at any point in your development process.

4. Enhance designs through automated modeling and generative design

Automated modeling and the Generative Design Extension enable you to quickly generate viable ideas based on constraints. Explore new nontraditional design opportunities using automated modeling, or take things a step further with generative design to incorporate considerations such as manufacturing methods, design constraints, or costs.

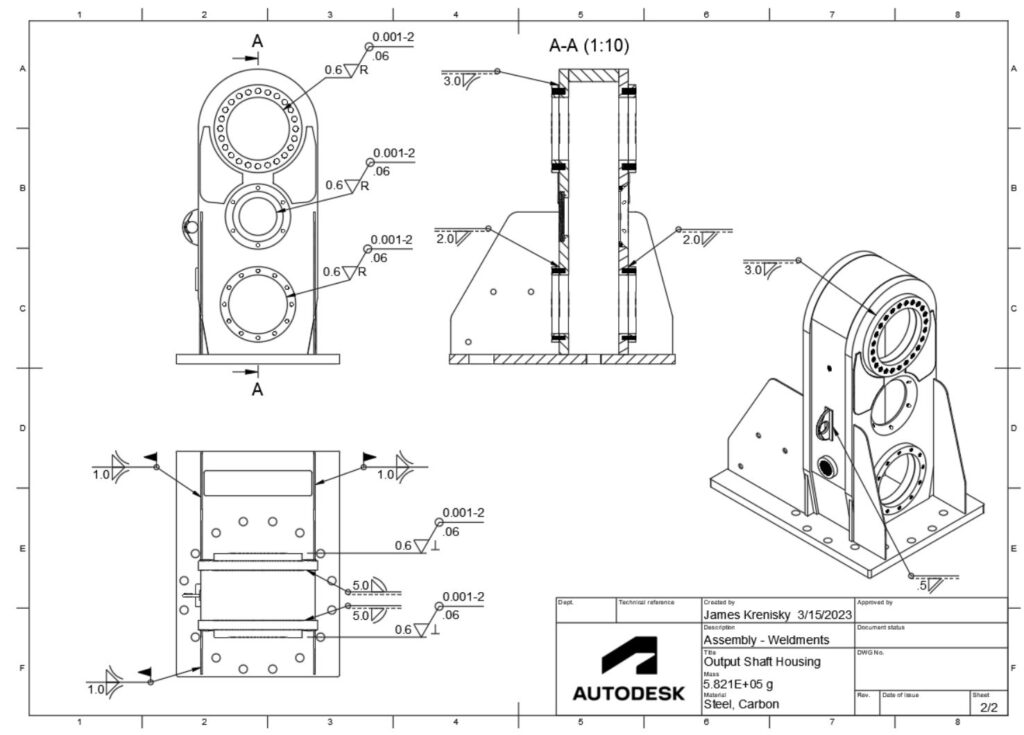

5. Generate detailed manufacturing drawings

Providing clear, accurate, and easy-to-follow documentation to manufacturers is indispensable. The Drawings Workspace in Fusion 360 ensures that your design intentions are communicated clearly, minimizing any potential misunderstandings or discrepancies. Publish your product’s fabrication plans, complete with intricate model and assembly illustrations, to effectively communicate essential production information.

6. Incorporate electrical components with ECAD/MCAD

Today’s competitive consumer product landscape calls for advanced PCBs and schematics. Why not design them with the same tool you use for 3D modeling? Fusion 360 is one of the only products that offers integrated ECAD and MCAD.

Additionally, 90% of boards fail without running simulations before fabrication. For those who want to unlock more ECAD capabilities, The Fusion 360 Signal Integrity Extension tells you everything you need to know visually before fabricating a PCB prototype.

7. Simulate Finite Element Analysis (FEA) and Design for Manufacturability (DFM)

It can never hurt to ensure your ideas are structurally sound before spending budget on fabrication. Static Simulation (stress testing) is a core capability in Fusion 360. And if you want to unlock even more advanced simulation tools, try the Simulation Extension.

8. Create parts for sheet metal fabrication

The Nesting & Fabrication Extension extends the sheet metal capabilities in Fusion 360 by enabling you to create optimized and associative multi-sheet layouts for cutting on CNC machines.

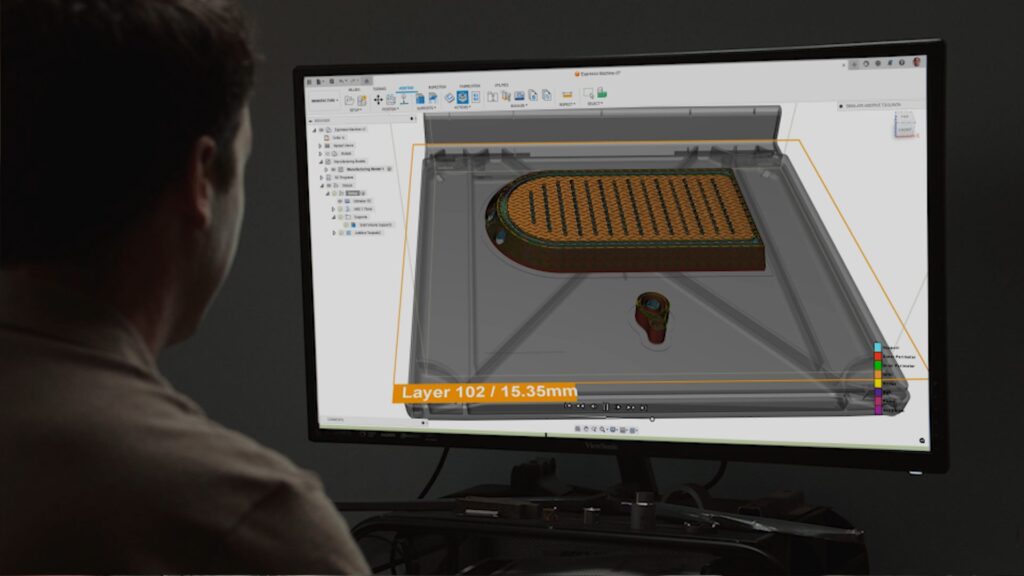

9. Generate toolpaths for additive (3D printing) and subtractive (CAM) processes

Once a design is ready for physical testing and review, components can be manufactured with additive manufacturing processes, ranging from FFF to metal additive, or CNC machined with subtractive CAM toolpaths. This dual approach ensures designs are optimized for both additive and subtractive manufacturing, ultimately leading to faster prototyping, higher-quality end products, and reduced time-to-market.

10. Post-process for defects through in-canvas rendering

Fusion 360 enables you to create quick renderings that are ideal for post-processing and high-level concept presentations. Renderings also come in handy when working with plastic injection molding, as visualizing your final product early on is essential.

Fusion 360 is your ultimate product development tool

Whether you’re starting a business or looking to streamline an existing team workflow, Fusion 360 solves all of your prototyping and fabrication needs. Are you ready to move through the product development process with confidence? Harness the power of Fusion 360 to expedite your prototyping needs and gain a competitive edge in today’s fast-paced market.