This post is also available in: Français (French) Italiano (Italian) Deutsch (German)

Autodesk Fusion 360 is a comprehensive ecosystem that redefines what’s possible in design, engineering, and manufacturing. Whether you’re designing intricate engine parts, simulating thermodynamic properties, generating toolpaths for manufacturing, or even collaborating in real-time with global teams, the capabilities in Fusion 360 are nothing short of incredible.

From day one, we’ve committed to delivering power, flexibility, and unparalleled performance to all, and we’ve come a long way. If you haven’t looked at Fusion 360 lately, here are some design and engineering highlights you won’t want to miss.

Enhanced Productivity and Creativity: The Fusion 360 Product Design Extension

One of the most compelling offerings within the extensive suite of Fusion features is the Product Design Extension. This specialized extension elevates the engineering design process to a new level, simplifying complex tasks and enhancing overall productivity. The Product Design Extension is a vital asset for professionals who commit to achieving excellence in product development with functionalities spanning plastic part design to sophisticated simulation capabilities.

It’s for users who require advanced modeling tools, simulation, and documentation features that go beyond the standard offerings of Fusion 360. The extension is part of the Fusion approach to provide a modular and flexible environment where users can customize their toolset according to specific needs.

The extension also enhances surface modeling capabilities and plastic part creation. Thus enabling designers to create more complex and aesthetic geometries that can be crucial in consumer-facing products.

By adding the Product Design Extension to Fusion 360, professionals can significantly speed up the product development process, from conceptual design to manufacturing. It fills the gap between standard CAD features and specialized requirements. Ultimately making Fusion 360 a more versatile and comprehensive tool for product designers and engineers.

Volumetric Latticing

Particularly noteworthy is the extension’s ability for volumetric latticing. This function allows you to create complex yet lightweight structures that maintain strength and integrity. This is ideal for consumer product ideas, aerospace components, or advanced medical designs. Not only does this dramatically reduce design time and material costs, but it also opens doors for sustainable manufacturing practices.

Volumetric latticing in Fusion 360 refers to generating complex, three-dimensional lattice structures within a solid model to optimize material usage, mechanical properties, and weight. The volumetric latticing feature allows engineers and designers to replace the bulk material within a component with a lattice structure while retaining the part’s outer geometry.

Lattices can be customized in various ways. These include cell type, size, and density, to meet requirements like tensile strength, compressive strength, and weight. By utilizing volumetric latticing, designers can create parts that are not only lighter but also equally strong—or, in some cases, stronger—than their fully solid counterparts. This is especially beneficial in aerospace, automotive, and medical industries, where weight and material efficiency are critical.

To implement this, Fusion 360 provides a user-friendly interface to define the region for latticing. Once the lattice is created, the part can be analyzed using the simulation tools in Fusion 360 to ensure it meets the desired mechanical criteria. The final design can then be exported for additive manufacturing, a method well-suited for producing intricate lattice structures.

Fusion 360 Drawings: Detailing Made Easy

When documenting your designs for manufacturing, the drawing workspace in Fusion 360 is your go-to resource.

The Drawings workspace in Fusion 360 is a dedicated environment for creating detailed 2D engineering drawings from 3D models. This workspace is an essential bridge between digital design and a part’s physical manufacturing or construction. With its user-friendly interface, the Drawings workspace allows engineers and designers to generate drawings that adhere to industry standards, complete with dimensions, annotations, notes, and other pertinent details.

Within the Drawings workspace, you can easily project views from a 3D model onto a 2D plane, offering multiple standard view options such as top, front, side, and isometric views. These projections serve as the basis for adding dimensions, tolerances, and other specifications necessary for manufacturing. Auxiliary views, section views, and detail views can also be added to highlight specific features or complexities of the design.

One of the most valuable features is the dynamic link between the 3D model and the 2D drawing. Any changes made in the 3D model are automatically updated in the drawing. Thus ensuring consistency and reducing the likelihood of errors. This is crucial in industries where small mistakes can lead to significant problems or costs.

The Drawings workspace also supports exporting the finished drawings into formats such as PDF and DWG, facilitating easy sharing with clients, colleagues, or manufacturers. Overall, the drawings workspace provides a robust set of tools for translating intricate 3D designs into precise 2D documentation.

Automated Modeling: A Future in Design

Automation in Fusion 360 isn’t limited to drawings. It also extends to modeling. Using generative design algorithms, Fusion 360 enables you to input design parameters and sit back as the software generates multiple optimized solutions. This dramatically reduces the iterative cycles traditionally required in design processes, letting you fast-track your projects.

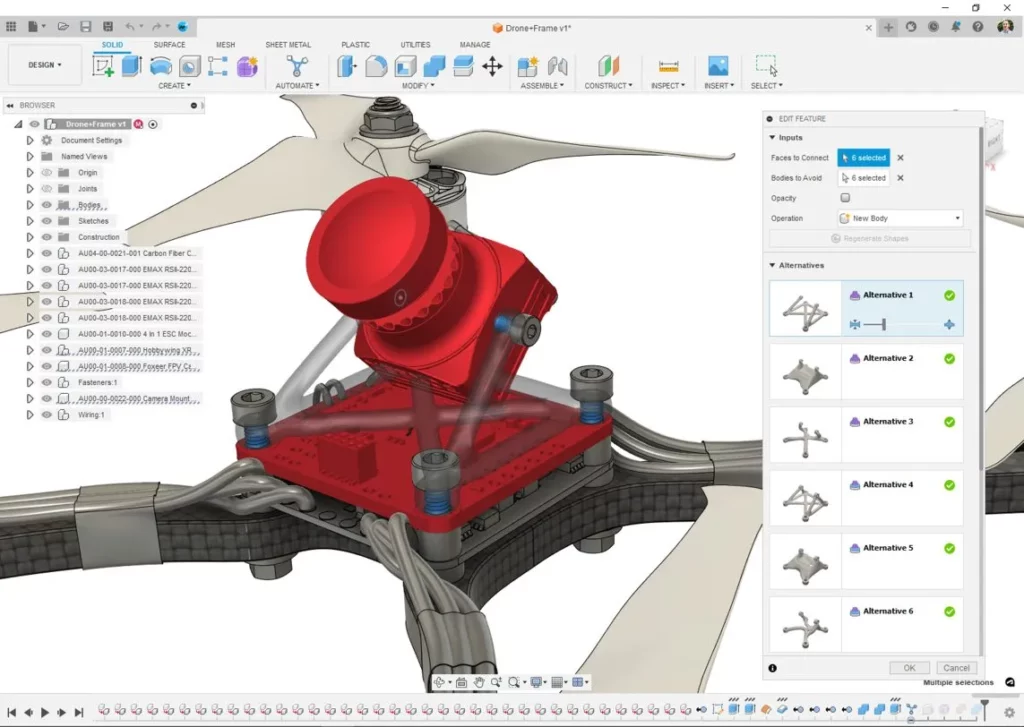

Unlike traditional modeling commands like Loft and Sweep, which are restricted to connecting a start and an endpoint, or Generative Design, which requires substantial preparatory inputs like loads and constraints, Automated Modeling offers a more balanced approach. Accessible in the Design Workspace, this tool allows you to specify basic parameters such as “Faces to Connect” and “Bodies to Avoid.” With these inputs, it leverages generative algorithms to produce multiple design variations in just minutes.

This tool serves multiple purposes:

- It speeds up the initial design phase by instantly presenting various design alternatives that conform to primary spatial constraints, thereby accelerating the ideation process.

- The generated results can serve as starting points for more detailed development, whether used as-is or refined further according to specific requirements.

- Because the tool generates multiple design alternatives, it encourages out-of-the-box thinking, allowing you to approach familiar problems innovatively.

Automated Modeling in Fusion 360 is both a time-saver and a creativity enabler. It simplifies the generative design process, offering a quicker, more straightforward path to viable design options. With minimal setup, you can explore various solutions, empowering you to tackle design challenges with increased efficiency and creativity.

Performance Improvements: Optimizing Your Experience

Continual performance improvements in Fusion 360 enhance what you can do and expand where and how you can do it. For instance, the software runs natively on Apple Silicon, offering up to 30% faster computing speeds and nearly 50% less battery consumption.

Enhanced User Interface

UI improvements like the native macOS trackpad engine for gesture processing and high DPI scaling support on Windows significantly enhance the user experience. Crisp fonts, icons, and smooth canvas navigation bring more fluidity to your design process.

Assembly Performance

If you frequently work with assemblies, you’ll be pleased to know that Fusion 360 has significantly improved in this domain. Now, tasks like ‘insert into current design’ are up to 84% faster, making your workflow more efficient.

The Power of Cloud-Native Capabilities

One of the pillars of Fusion 360’s prowess is its cloud-native architecture. Whether you’re a single user, a burgeoning startup, or an established enterprise, the software’s cloud capabilities make it infinitely scalable and accessible. Real-time collaboration, cloud rendering, and online file management make Fusion 360 a universal design solution.

Seamless Design for an Interconnected World: Fusion 360 is the Future of Engineering and Manufacturing

In an increasingly interconnected and fast-paced world, Fusion 360 stands out as the cloud-native, all-in-one design ecosystem that scales with your needs and skill level.

The software’s continual performance improvements mean that regardless of your industry or business size, Fusion 360 provides unparalleled value. It’s not just a design tool. It’s your partner in bringing ideas to life, optimizing workflows, and achieving efficiencies that were once considered impossible.

So why settle for anything less?

Learn more and try Fusion 360

Unlock the full range of design and engineering possibilities today with Fusion 360. Check out the other articles in this series to explore all that Fusion 360 has to offer:

- Eliminate Silos in Product Development with Autodesk Fusion 360

- Powering Your Products: Autodesk Fusion 360 Electronics Highlights You Don’t Want to Miss

- All About CAM: Autodesk Fusion 360 Manufacturing Highlights You Don’t Want to Miss

- Collaborating in Fusion 360: Data Management Highlights You Don’t Want to Miss

- How to Troubleshoot Fusion 360 Performance Issues

Get started with a free 30-day trial.