This post is also available in: Italiano (Italian) Deutsch (German)

Explore how Dan Lee Boatbuilding takes early 20th-century boat designs and creates a 21st-century digitized building experience.

You could say that Dan Lee’s vintage boat design business came from a perfect storm of passions combining.

First off, he has a life-long love of boats and boating. With his expertise in woodworking and interest in technology, he designed and built his own vintage boat for the first time a few years ago. At the end of the process, he thought it was something he’d really like to do for a living, and he noticed a growing demand for vintage boats. But then COVID-19 struck.

For years, Lee collected antique “build your own boat” design plans from the 1920s and 1930s that were often packaged with magazines. During the pandemic, he had the idea to take those early 20th-century designs and create a 21st-century digitized building experience.

“While I was building my first boat, I also had a business making shelving and furniture, so I was establishing the workshop at the same time,” Lee says. “During the first lockdown, I was worried about my main business. I started looking for extra things to do for a second income. That’s when I started drawing up these vintage boat plans.” And his company, Dan Lee Boatbuilding, was born.

Making What’s Old New Again

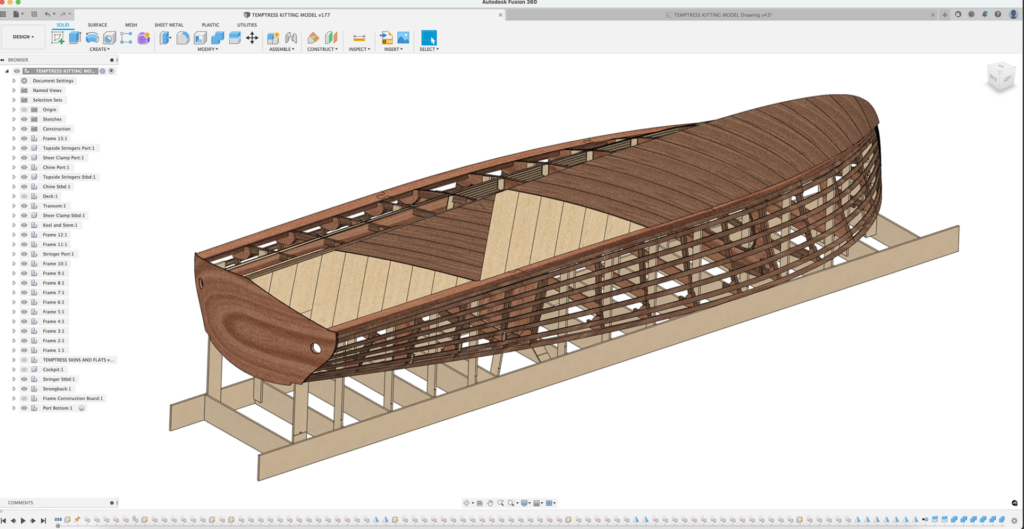

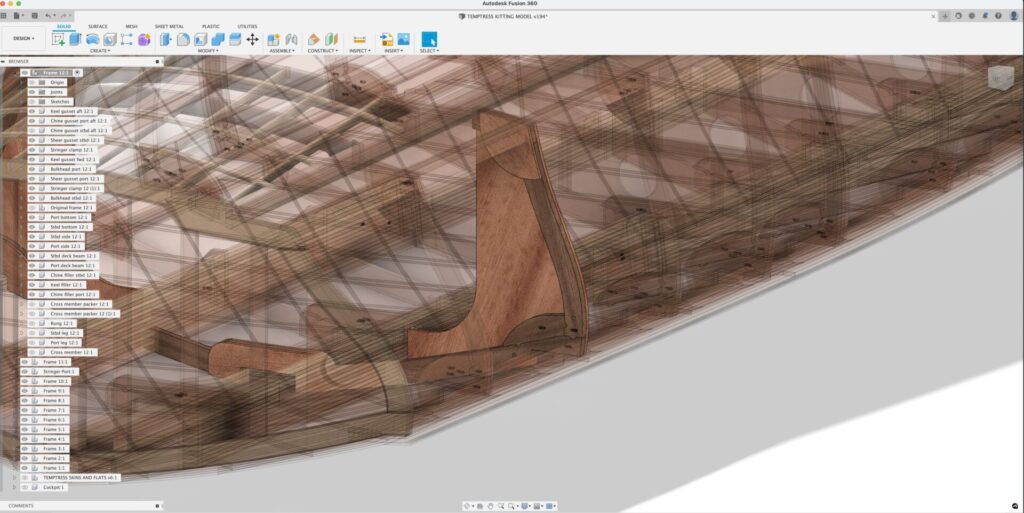

In Lee’s office, you’ll see the many antique boat plan books and booklets on the shelf behind his desk. The main challenge with those boat plans is a “table of offsets,” which contain numbers for the width and height of various points throughout the boat. According to Lee, it’s a daunting process. He began to take these plans and design them in Autodesk Fusion 360 for anyone to build.

“I had this idea that you could draw it all in CAD and create full-size patterns for each part,” Lee says. “Then anyone could just go to a CNC shop, get the pieces cut, and go straight into putting pieces together.”

These new plans for the vintage boats are completely digital, including an STP file, PDF files, and DXF files of CNC cuts nested in groups by material thickness and type. Semi-professional boat builders and first-time builders alike can choose from a variety of designs and degrees of complexity. “I want to create a bit of variation, so there’s a boat for all people,” Lee says.

Expanding to New Business Opportunities

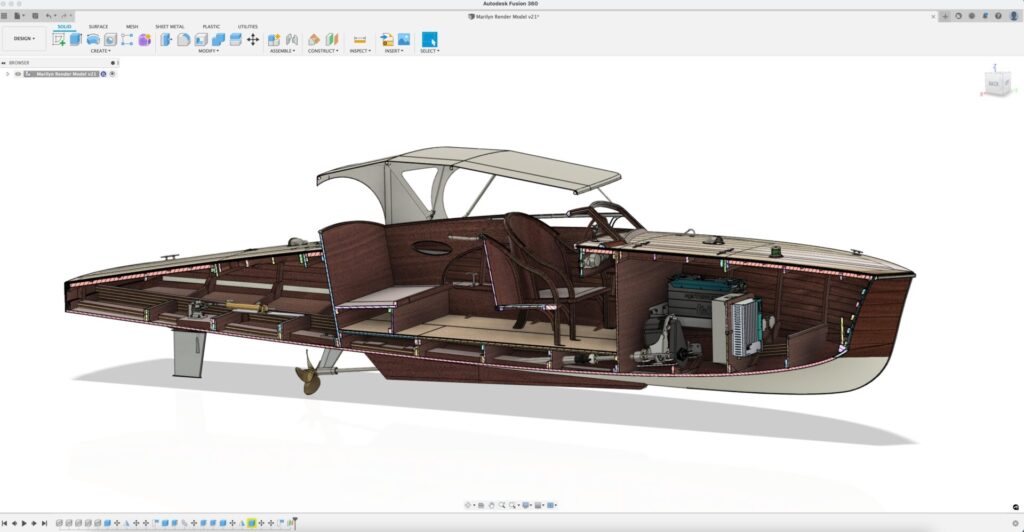

Lee’s burgeoning boat business started with modernizing the boat plans. But now he’s expanding to more restoration work and designing new boats from scratch with a designer in the United States. They’re still vintage and classic-looking. But underneath the surface, they have adopted modern construction techniques along with CAD and CNC.

“It’s sort of keeping things classic but moving with the times as well,” Lee says. “The designer does the boat structure framework and sends it to me. I effectively ‘kit it’ in Fusion 360 and turn it into nested parts. I do all the jointing in the frames and make all the jigs and alignment items. Basically, with Fusion 360, I can turn it from a drawing into a kit of parts that you can then pass to a manufacturer to get the kit made.”

Lee even transparently shares his process on YouTube so that others can learn:

Parametrically designed steering wheel

His creativity with Fusion 360 and boats don’t ever seem to idle. Recently, he met another fellow boat enthusiast who wanted an antique steering wheel like the one on Lee’s original boat. But these steering wheels are often hard to come by due to age. So they decided to manufacture it themselves.

Lee quickly drew the set of spokes in Fusion 360, sent off the design to be 3D printed, and they just finished casting the wheel in aluminum.

“I actually drew all of the spokes parametrically so we could tweak the width of the spokes and the thickness of them,” Lee says. “We played around with the design a little bit until it was what he wanted and then it went off for the 3D printing in order to cast the sand molds. It’s a great advantage to be able to do that.”

“I think having everything all in one package is great, and that’s what Fusion 360 is all about,” he continues. “I can produce renders and jump into CAD and do tool paths. It’s one software that does everything I need without having to export a model and then render it in something else. And if you change something, then you don’t have to export again. It’s all just there all in one place at the same time.”