DESIGN & MANUFACTURING

Integrated factory modeling

Respond to changing markets with an agile, innovative factory.

DESIGN & MANUFACTURING

Respond to changing markets with an agile, innovative factory.

Integrated factory modeling combines BIM and digital factory planning to generate a digital representation of production facilities and equipment. Multi-disciplinary project contributors can collaborate in this central, always-up-to-date model to plan, design, validate, build, and operate factories.

Depending on the complexity of the project, industrial processing systems provider GEA cuts engineering time anywhere from 30% to 80%.

Electrical vehicle manufacturer e.GO saves up to 35% by focusing on modern design practices and integrated factory modeling.

Frumecar reduces around 70% of the costs caused by process incidents and drastically shortens start-up times by using virtual manufacturing tools.

Digitalization is enabling manufacturers to usher their factories into a new era of individualization, functionality, and sustainability. Harvard Business Review Analytic Services interviewed industry leaders to see how they’re future-proofing manufacturing operations with integrated factory models.

Reduce risk by giving everyone access to reliable, real-time design and operational data. Connect market demand data to your supply chain to drive manufacturing output and quality.

Ensure your building systems provide the required support. Better plan and coordinate by visualizing production lines in the context of your facility, and monitor performance with real-time data.

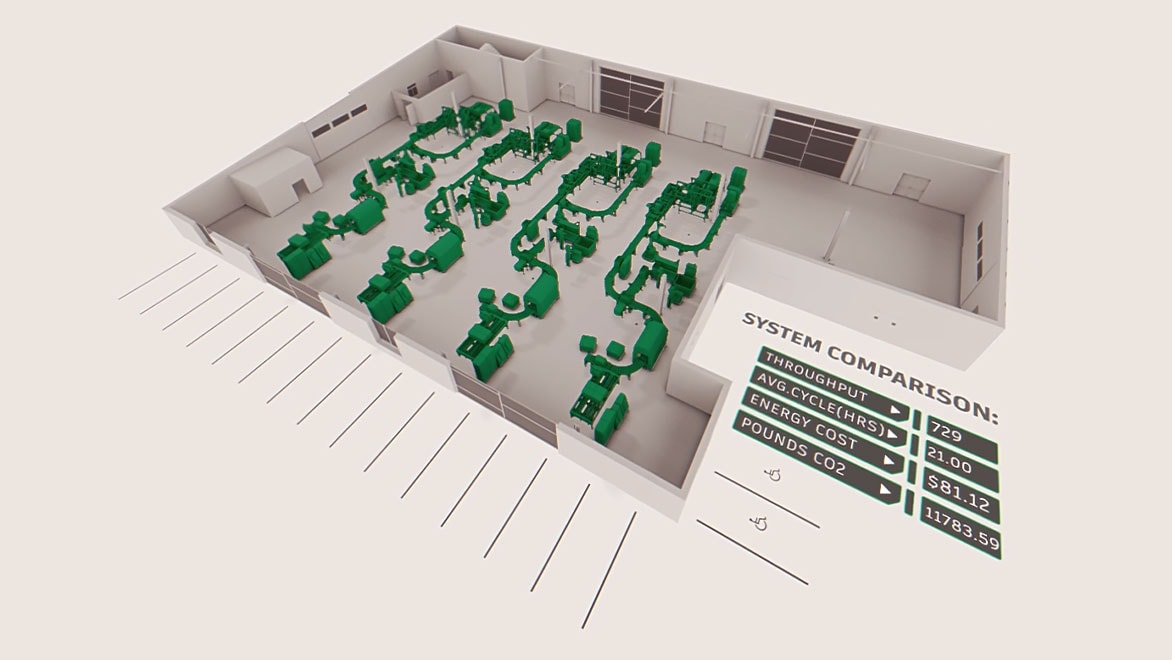

Optimize your production output using your coordinated model to simulate alternatives. Use real-time data from a digital twin to reduce downtime and provide insight into operational efficiency.

Leverage integrated factory models as always-up-to-date digital twins—useful for maintenance, service, and change management.

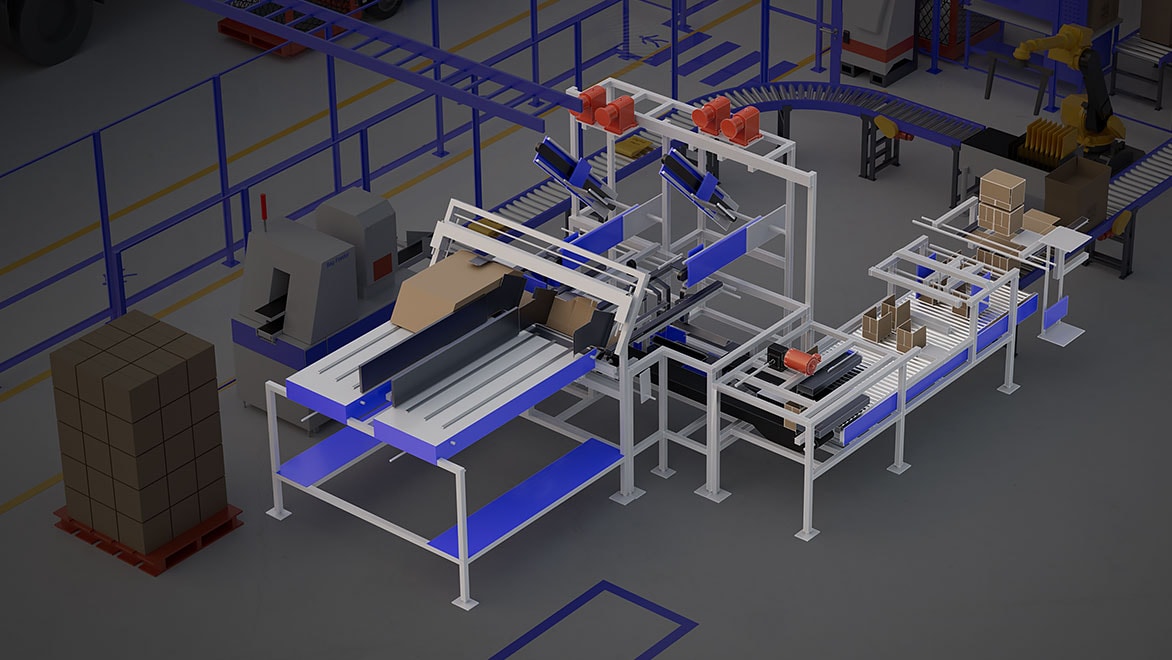

Integrate models of industrial equipment with the model of the production facility in a unified Building Information Model.

Create intelligent Building Information Models of production facilities with multi-disciplinary data integrated in one digital, cloud-enabled representation.

Use AnyCAD to integrate 2D and 3D models from any CAD application, with current condition point cloud scans, into a unified factory model.

Manage data from all disciplines in a common environment for real-time collaboration, seamless project execution, and closed-loop factory lifecycle management.

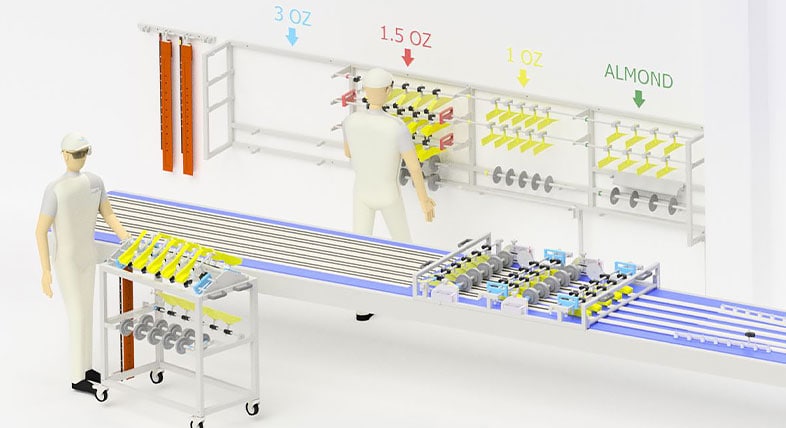

Design, plan, and validate large-scale systems and work cells with specialized 2D and 3D toolsets purpose-built for production system design.

Easily understand and communicate facility designs by creating realistic renderings and animations of production facilities from 3D models.

Accelerate installation and reduce change orders by planning and simulating construction sequences that can be shared with contractors, trades, and suppliers.

BRIOCHE-PASQUIER

Brioche-Pasquier builds a digital twin of their sites that includes their equipment, scan data, production layouts, and building models.

PORSCHE

To make their first electric sports car, Porsche used integrated factory modeling to create a smart facility—one as green as the car it manufactures.

SAFRAN

Using digital factory tools, multiple project teams at Safran can work within the same 3D model to coordinate decisions backed by reliable BIM data.

By leveraging Autodesk digital factory solutions, you can enhance your operations and deliver positive business outcomes. Integrated factory modeling helps you optimize your factory layout to minimize downtime, increase energy and material efficiencies, and improve communication and data insights.

As a global leader in the integration of architecture, engineering, construction, product design, and manufacturing processes, Autodesk can help you develop the capabilities needed to achieve your goals.

Reach out today to schedule your business consultation.