& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

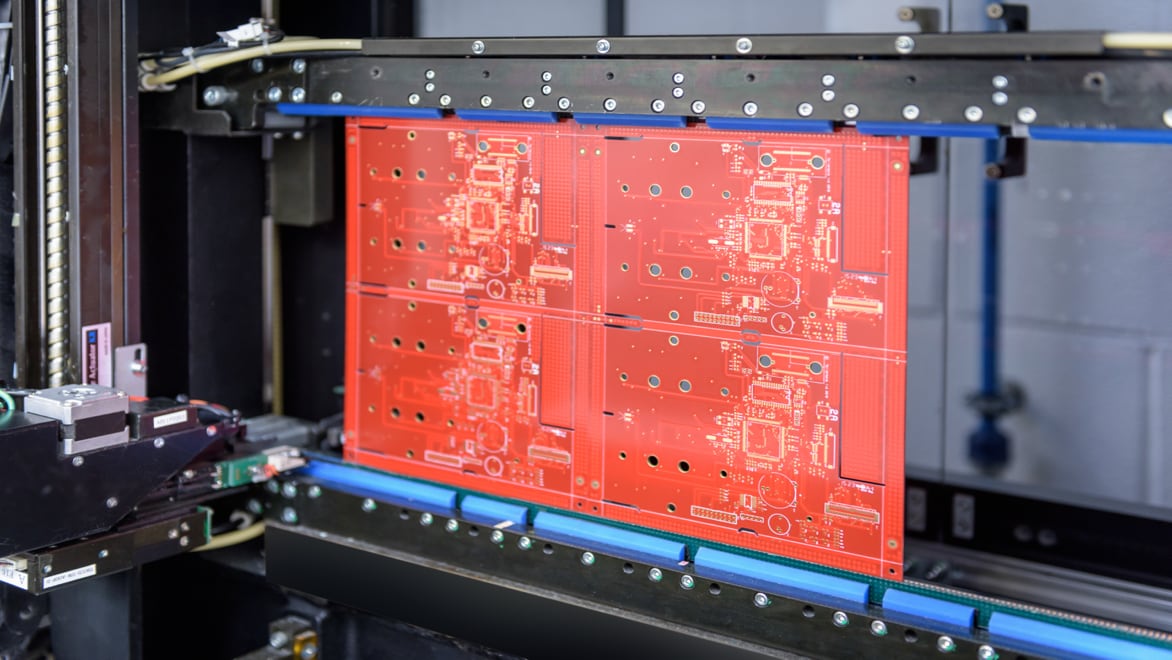

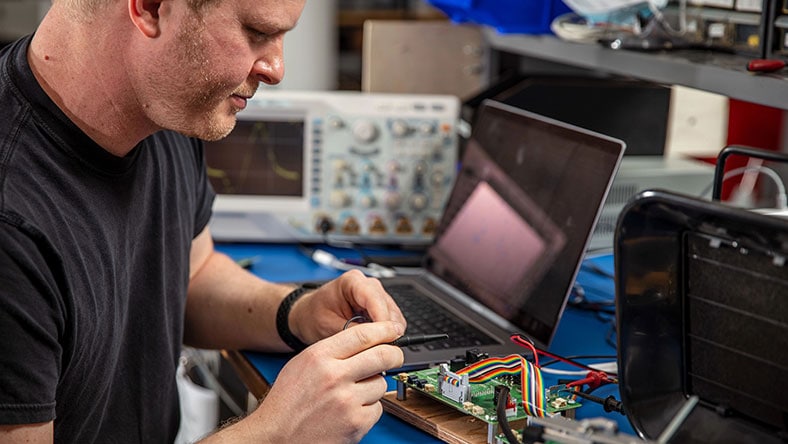

PCB manufacturing, also known as printed circuit board manufacturing, produces printed circuit boards. A printed circuit board is the foundation of most electronic devices. The circuit board consists of a panel made of non-conductive material (typically fiberglass or composite epoxy) that supports and connects electronic components using conductive pathways etched or printed onto its surface.

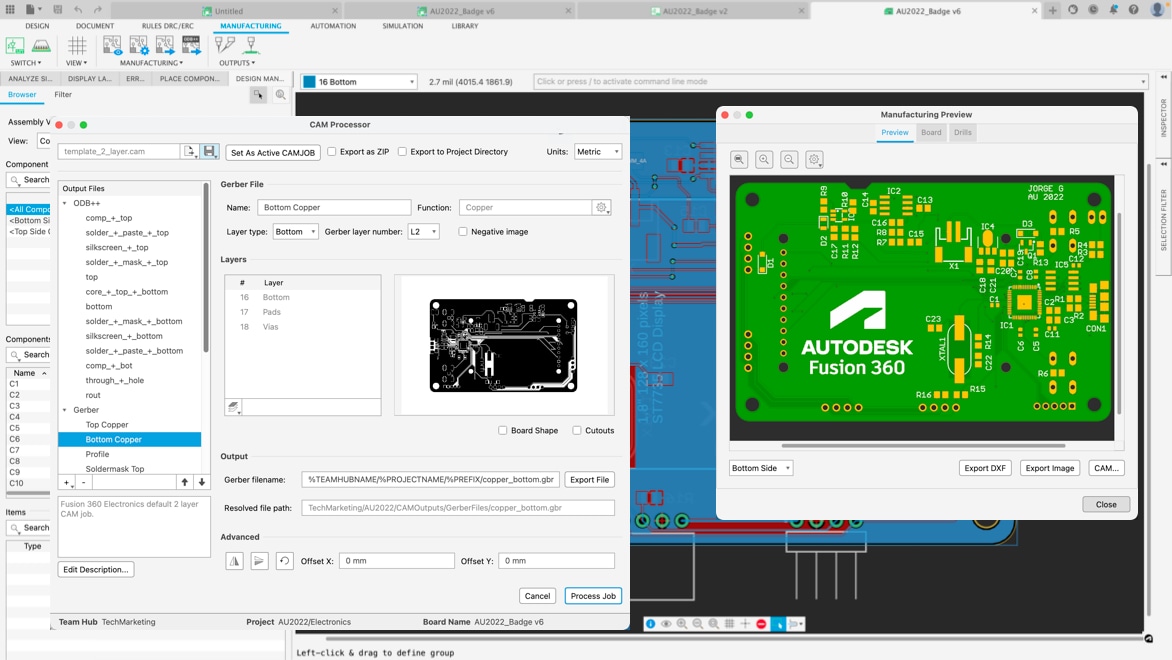

Fusion 360 is the future of product design, and the electronic workspace has a critical role in this digital platform. Fusion 360 electronics will allow your engineering team to implement the electronics required to make your product work. An essential step after designing your PCB is generating your PCB manufacturing files. This critical step traditionally consisted of multiple efforts that were error-prone. Fortunately, Fusion 360 offers a range of options that simplify this traditionally complex task, making it just a few simple steps.

Fusion 360 includes the conventional Gerber and drill outputs accepted by all manufacturers but also includes smarter export such as ODB++, which facilitates manufacturer simulation. From one-click export to fully manual configurable CAM exports are available.

PCB manufacturing software, like Autodesk Fusion 360 enhances the productivity and effectiveness of the design and manufacturing processes, leading to higher-quality PCBs, reduced development time, improved collaboration, and cost savings with less re-spins.

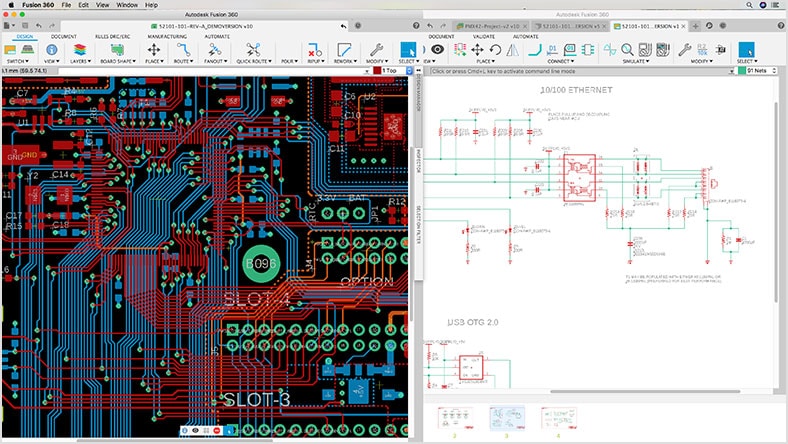

PCB manufacturing software, like Autodesk Fusion 360, offers electronics engineers powerful Electronic CAD design tools that empower you to effortlessly create, modify, and optimize circuit layouts, component placement, and trace routing according to manufacturer preferences which streamline the entire design process.

Fusion 360 data management enables real-time collaboration, version control, and the sharing of design files, making it easier for teams to collaborate effectively, exchange feedback, and track design changes throughout development.

PCB manufacturing software include design rule checks (DRC) to make sure that the layout conforms to manufacturing and industry standards. They can also simulate and analyze electrical performance, signal integrity, and thermal characteristics to help resolve potential issues before fabrication.

PCB manufacturing software provides tools for optimizing the design for manufacturing (DFM). It helps identify issues such as component placement, spacing, and solderability. This helps reduce the likelihood of errors, minimizes rework, and lower production costs.

Taking a printed circuit board from the initial design phase to final assembly and construction involves three primary stages:

The initial stage begins with taking an idea for a circuit board and turning it into a design file. PCB design software can help create iterative schematics and refine PCB designs for optimized layouts.

PCB fabrication is the manufacturing stage of the process that creates the physical components of a printed circuit board based on the specifications provided in the initial PCB design schematics.

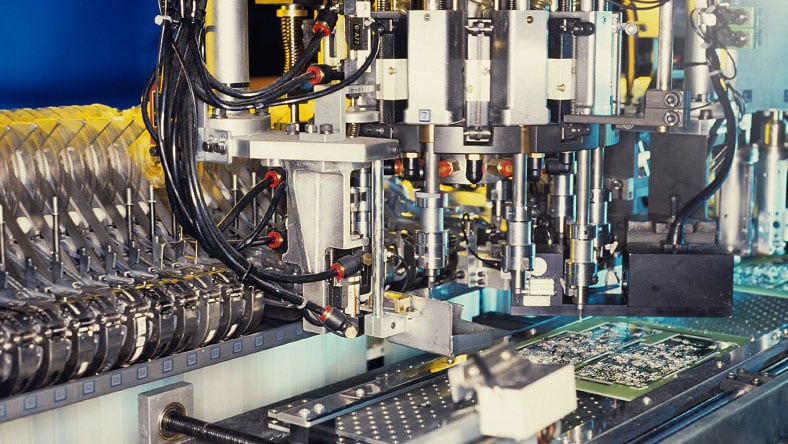

PCB assembly (PCBA) is the final stage of printed circuit board construction that utilizes a soldering process to mount the fabricated components onto an empty board in the layout from the design phase.

Fusion 360 empowers designers with cutting-edge simulation tools to meticulously assess the electrical performance of PCB designs. From comprehensive thermal analysis to precise electromagnetic interference (EMI) analysis, this all-in-one solution guarantees unparalleled optimization and unwavering reliability.

Fusion 360 Electronics offers unparalleled PCB layout capabilities, empowering engineers to efficiently create intricate and precise circuit board designs. This software ensures optimal electronic design performance, reliability, and manufacturability with advanced features such as violator mode options, efficient routing algorithms, and simple setup design rule checks.

The library editor in Fusion 360 provides a seamless and efficient solution for managing and organizing component libraries. With its intuitive interface and powerful editing capabilities, designers can effortlessly create, modify, and share libraries, streamlining the design process. Package editor includes all IPC-compliant templates to develop your footprint and mapped 3D model in moments. This robust management tool enables designers to maintain an extensive collection of components or save time using the included repository of components.

Fusion 360 unleashes the power of immersive 3D visualization, enabling designers to transform their PCB designs into vivid three-dimensional representations. This game-changing feature reveals potential mechanical clashes and provides a holistic view of the PCB's form factor, empowering designers to optimize design choices with precision and foresight.

Design Rule Checking (DRC) in Fusion 360 ensures foolproof designs by automatically scanning and validating your PCB layout against a comprehensive set of predefined rules. With real-time feedback and instant error detection, you can confidently eliminate design flaws, minimize prototyping iterations, and accelerate time-to-market, ultimately delivering impeccable and reliable electronic products.

PCB manufacturing software aids in the creation of medical devices such as patient monitoring systems, diagnostic equipment, implantable devices, medical imaging devices, and laboratory instruments.

PCBs are manufactured for a wide range of consumer electronic devices such as smartphones, tablets, laptops, gaming consoles, smart home devices, audio/video equipment, wearables, and more.

PCB manufacturing software is used to create engine control units (ECUs), infotainment systems, instrument clusters, sensors, advanced driver-assistance systems (ADAS), and other automotive electronic components.

From vital sign monitors to portable ECG machines, PCB manufacturing software enables the creation of innovative and precise electronic components for medical applications.

Industrial automation systems use PCB manufacturing software to design and manufacture programmable logic controllers (PLCs), motor control boards, human-machine interfaces (HMIs), sensors, and other devices used in manufacturing and process automation.

PCB manufacturing software is used in the aerospace industry to create communication, radar, and navigation systems, drones, and military equipment.

PCB manufacturing software is used to create PCBs for robot controllers, sensor interfaces, motor control boards, and more.

Optimize PCB design electromagnetic performance by controlling the impedance of every critical transmission line.

Learn more about PCB manufacturing with the following resources from Autodesk.

Follow this PCB manufacturing advice, and your PCBs will cost less, have fewer production failures, and overall better quality.

Don’t break the bank – save money with these ten practical PCB manufacturing tips.

Ever wonder what kind of DFM mistakes you can make that will drive your PCB manufacturer absolutely crazy? Learn about the top 10, so you don’t make them in the future.

Explore courses and skills that help you become an Autodesk Certified Associate in CAM for 2.5 Axis Milling. Learn at your own pace, track your progress, and determine your path forward.

Are you new to PCB design or a seasoned pro learning Autodesk Fusion 360? Learn the basics of how to work with 3D PCB in Fusion 360.

PCB design revisions used to be costly and time-consuming. Not anymore! Here’s why PCB designers need 3D modeling software.

Yes, Fusion 360 is suitable for small-scale PCB manufacturing. It offers a range of features and tools that cater to the needs of small-scale manufacturers and hobbyists. The software's intuitive interface, collaboration capabilities, and integrated manufacturing documentation make it an ideal choice for small-scale PCB production.

Yes, Fusion 360 supports the import of existing PCB designs. You can import designs from other PCB design software or file formats, such as Altium Designer, Eagle, or Gerber files. Fusion 360's import functionality allows you to retain the integrity of your design and continue working on it within the software.

Yes, Fusion 360 supports collaborative PCB design. Its cloud-based platform enables real-time collaboration among team members, allowing multiple designers to work on the same design simultaneously. Fusion 360 provides version control, comment features, and design sharing capabilities to facilitate efficient collaboration throughout the design process.

While Fusion 360 ECAD software works with Macs and Windows operating systems, not all ECAD software are Mac compatibles. If you own a Mac, check the minimum requirement section of the ECAD software you intend to purchase.

Absolutely! Fusion 360 offers a user-friendly interface and intuitive tools that make it accessible for beginners. The software provides step-by-step guidance and extensive learning resources to help users grasp the fundamentals of PCB design and layout creation.

AutoCAD is a computer-aided design (CAD) software that is used for precise 2D and 3D drafting, design, and modeling with solids, surfaces, mesh objects, documentation features, and more. And while Autodesk's AutoCAD Electrical toolset includes all the features and tools you need for electrical design, it's not best suited for PCB Design. Autodesk Fusion 360 on the other hand, is a comprehensive tool that can be used for modeling, CAD, CAM, CAE, as well as PCB Design and manufacturing.

PCB (printed circuit board) manufacturing is a process that involves the fabrication and assembly of printed circuit boards. ECAD software can be used to create a digital workflow to streamline everything from PCB schematic design and layout through final board construction. And regardless of the various technologies each manufacturer utilizes, the majority of the industry-leading facilities follow a specific set of steps to turn a design from the design data package to physical boards. The steps in this process are usually as follow:

While FR-4 is the most commonly used material for PCB design, there are several material choices to consider based on the unique design needs. Before selecting a material, it is recommended to first define the functionality and reliability requirements that the board must meet. As an example, PCBs that are involved in applications requiring high temperatures, would require specific temperature characteristics than PCBs that would be used in a smart home product. These requirements will typically include:

In addition to the above, other things to consider when it comes to PCB material are:

Several different factors will affect the cost of PCB Manufacturing software, but in general, you can expect them to be between $500 and $4000 per year (subscription)