& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

The Autodesk Fusion Simulation Extension empowers your team to analyze part performance, manufacturability, and generative design capabilities.

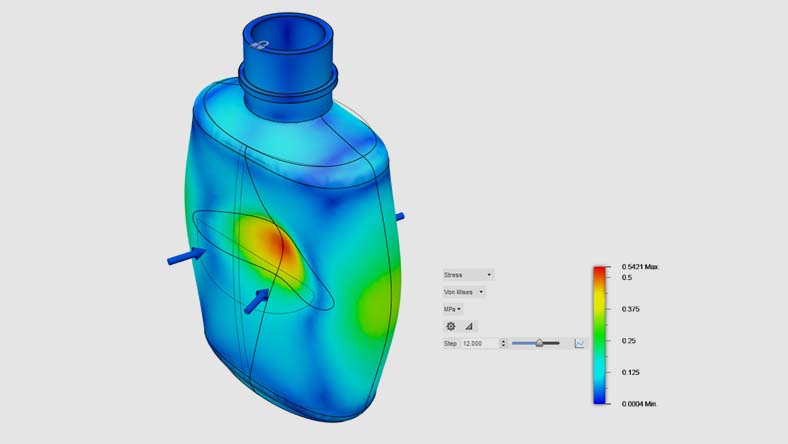

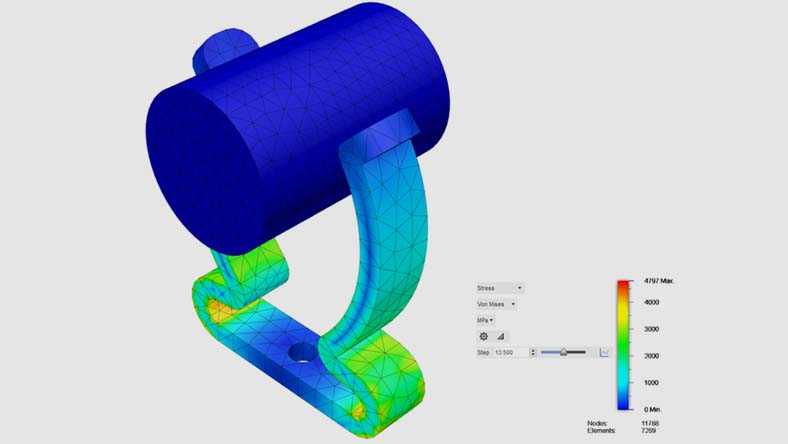

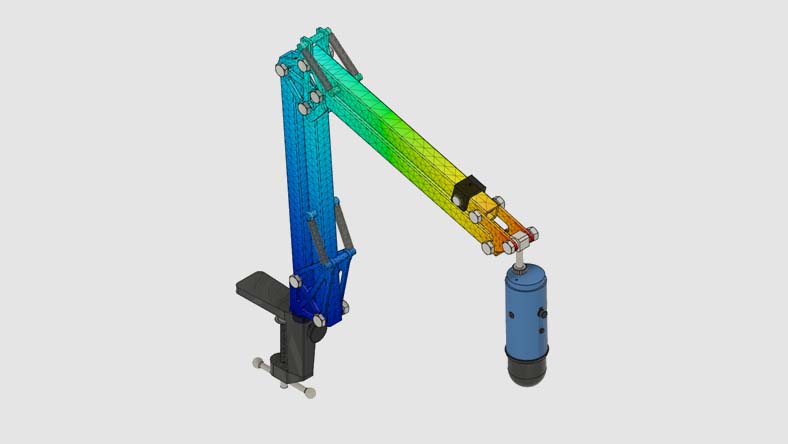

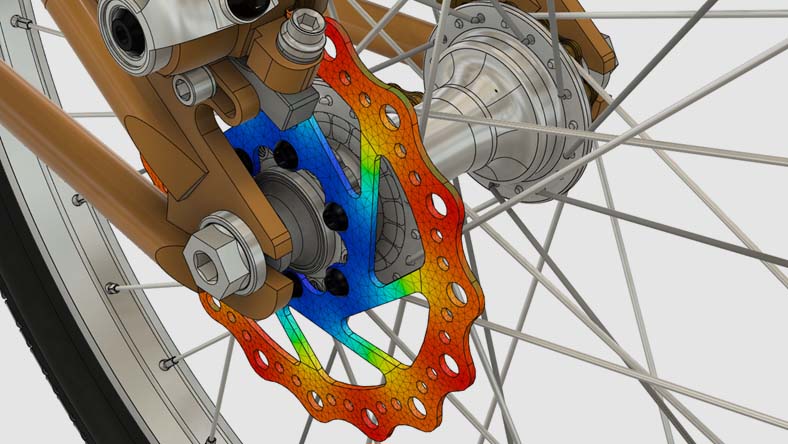

Generative design outcomes can help you discover weight reduction and performance enhancements. Combine this with simulation study types like structural, thermal, and explicit simulations, as well as injection molding to gain a comprehensive understanding of how your 3D design will perform under real-life conditions before manufacturing.

Automate performance and reduce design costs with generative design. Minimize physical prototypes with digital prototypes using simulation tools.

Access advanced simulation study types to validate real-world design performance through side-by-side design comparisons.

Use manufacturing process-aware artificial intelligence to quickly expand design options well beyond human imagination.

Simulate large deformation, motion, contact, and load change behaviors on nonlinear materials.

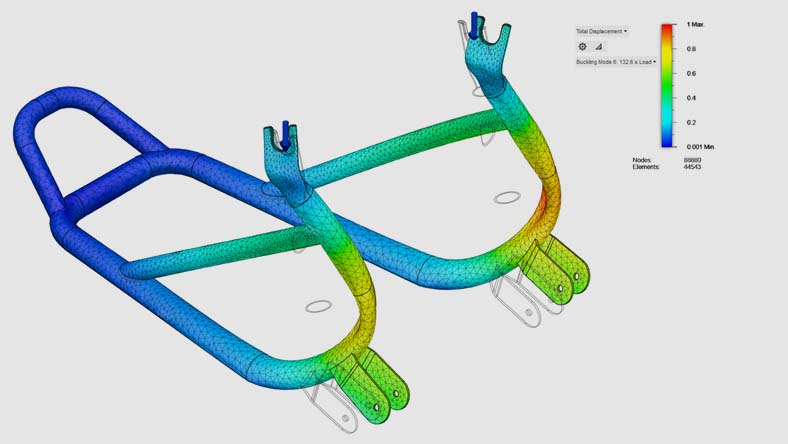

Develop and refine designs to prevent structural failure with insights like the critical buckling multiplier.

Predict how time-dependent forces influence 3D design performance.

Inspect the effects of natural, free vibration on your part or assembly to help you fine-tune your design.

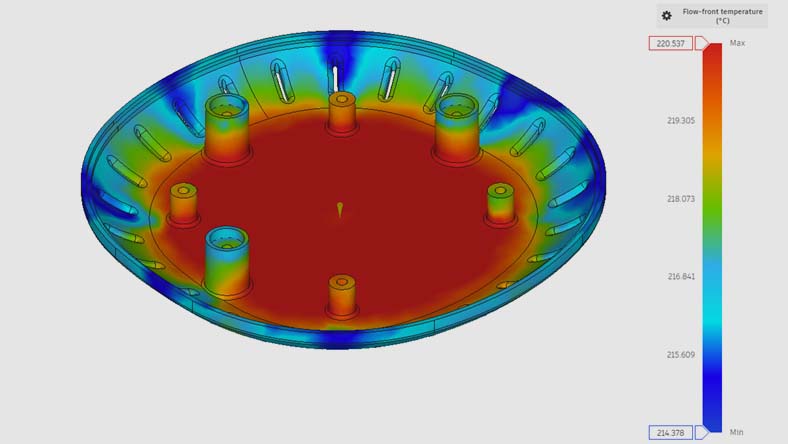

Learn how part design influences part manufacturability and part quality for plastic injection molded parts.

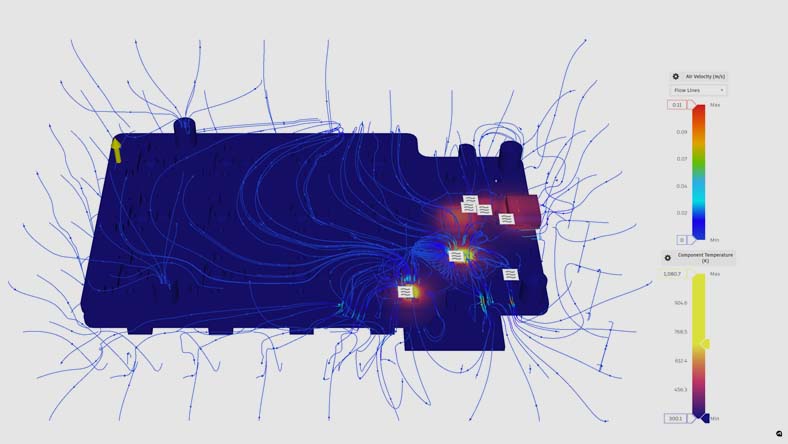

Identify risk of electronic component and part failure due to overheating on your printed circuit board (PCB) assemblies.

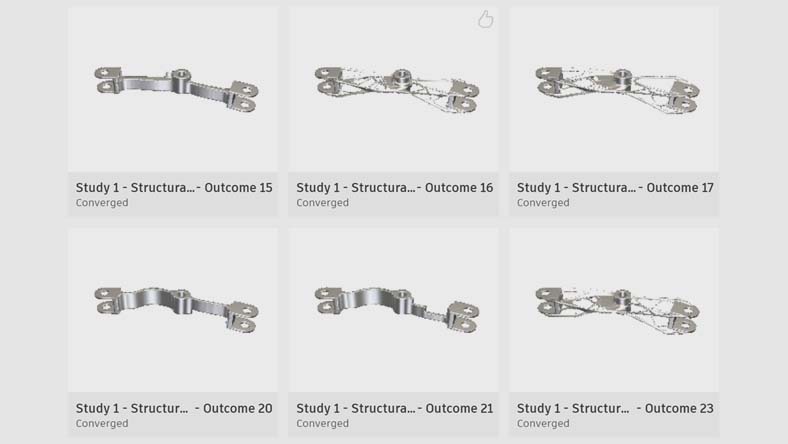

Explore multiple outcomes that meet your design specifications while reducing weight and improving performance.

Trace heat transfer and temperature-induced stresses with thermal steady state and thermal stress simulations.

The Autodesk Fusion Simulation Extension is a set of simulation study types to help you evaluate how your 3D design will perform, and how easy it can be made.

Analyze the performance and manufacturability of your 3D designs to make sure they will meet the demands of real-world conditions with structural, thermal, and explicit simulation tools.

The Simulation Extension also includes injection molding simulation studies to help you gain plastic injection molding manufacturing insights for your 3D design.

Generative design (formerly a separate Fusion extension) is now included within the Fusion Simulation Extension, granting capabilities to develop design outcomes beyond the human imagination.

Yes, the Fusion Simulation Extension has the same capabilities as the previous Fusion 360 Simulation Extension. The Fusion Simulation Extension also includes the features of the former Generative Design Extension.

Yes, the Fusion 360 Generative Design Extension capabilities are now included within the Fusion Simulation Extension.

The Autodesk Fusion Simulation Extension unlocks key insights of product design performance and quality through mechanical, structural, and injection molding analysis tools including:

The Autodesk Fusion Simulation Extension can be accessed using different payment methods to suit your business needs. For ongoing access, subscribe to the extension for 1-month or 1-year.

The Autodesk Fusion Simulation Extension offers flexible access to unlock professional grade tools as and when you need them. By comparison, stand-alone simulation programs tend to be point solutions, intended to provide limited simulation capability. Having access to various simulation studies within your CAD program promotes more insight into the part design while you design it.

Generative design leverages artificial intelligence and machine learning to generate multiple manufacturing outcomes that meet your design constraints while reducing weight, improving performance, and consolidating parts.

The outcomes created are native, editable CAD models so you can easily make modifications after they are generated. Generative designs include user-inputted constraints to generate designs based on manufacturing method, load constraints, materials, and manufacturing cost.

Topology optimization begins with a human-designed CAD model concept with loads and constraints applied based on the design constraints. Topology optimization returns only one optimized concept for evaluation based on the human-designed model. There is no automated ideation. Lastly, it returns to the user an optimized mesh design result that must be rebuilt in a CAD system that is intended for downstream use.

The Autodesk Fusion Simulation Extension begins with hold out areas, preserved areas, loads, and design constraints based on the project requirements.

Artificial intelligence generates the topological outcomes that are created for evaluation based design and manufacturing requirements. The Simulation Extension in Autodesk Fusion returns to the user a CAD ready geometry model that can be edited in any system.