& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

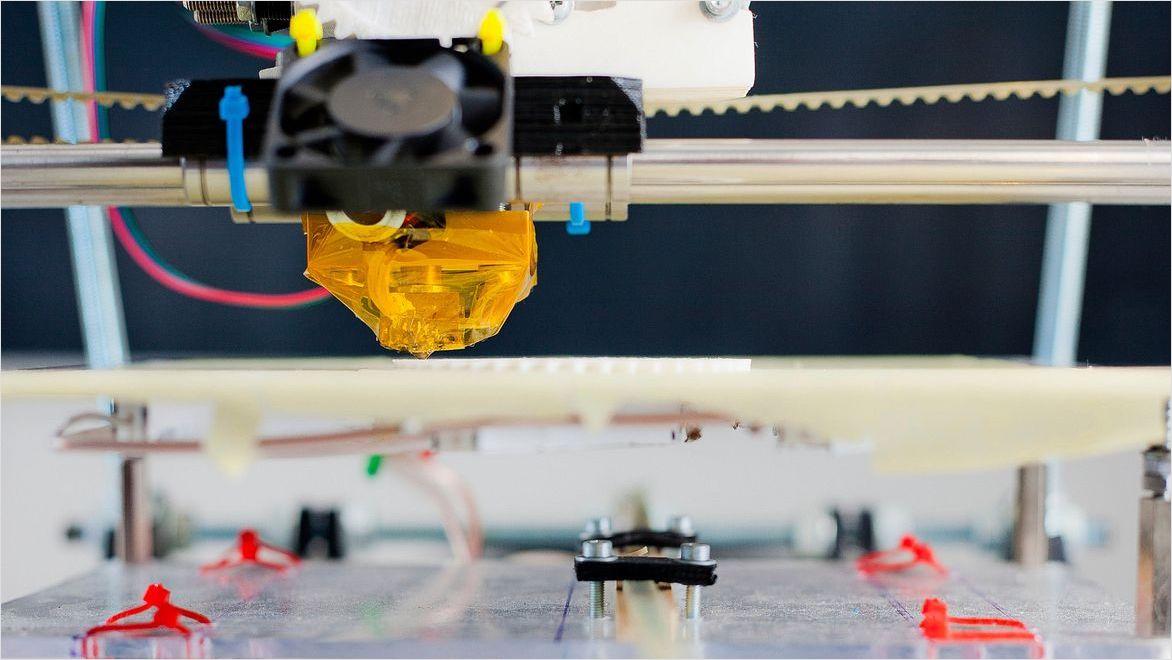

Stereolithography is an additive manufacturing process that converts a liquid resin into a solid, plastic- or rubberlike polymer in a 3D printer.

Also called SLA, stereolithography was invented in the early 1980s and entered the public consciousness as consumer and prosumer desktop 3D printing became popular in the early 2010s.

The SLA process uses a liquid resin that cures or solidifies when a laser of UV light is applied to the resin. This type of material, a thermoset, undergoes a chemical reaction when exposed to heat or UV light, hardening the liquid resin into a solid. Resins can come in assorted colors and are loaded into bottles that can then be added to the tank of the stereolithographic 3D printer. Once loaded, the printer can utilize the various colored resins to print.

As the printer applies liquid resin to an existing layer of the structure, the device shines a beam of UV light from a projector or laser. The resin’s chemical properties react to specific wavelengths of light emitted by the light, which cause the resin’s monomers and oligomers to join in chains, forming polymers (the basis of plastic) and hardening the material on the build surface layer.

Depending on the type of resin used, the final product’s physical properties can vary to suit the part’s end use better. These variations can include color, flexibility, durability, and weight.

Stereolithography differs from other popular 3D-printing methods in several ways. Fused deposition modeling (FDM) uses a thread or filament of thermoplastic in solid form, melting and extruding it onto the 3D model.

Selective laser sintering (SLS) also uses polymers, but the material is a powder. The 3D printer aims a laser at the powder, melting the polymer and fusing it into a solid form for the final structure.

FDM is most widely used in the prosumer/consumer and small-manufacturing markets alongside stereolithography. In contrast, SLS is more suited to heavy industry.

Among each type, stereolithography produces the smoothest, highest-resolution surface with material that’s watertight and reasonably shock absorbent in its final state. These properties make it the most popular method among home users and hobbyists.

The number of desk toys and trinkets produced in the early home 3D-printing movement are a good example of stereolithography’s utility.

The chemical properties of stereolithography resins make them popular in aesthetic and artistic fields, like jewelry and accessories. SLA is also widely used for making biomedical devices because of their nonabrasive finish.

Some 3D-printing methods produce rough builds and require postproduction processing to improve the surface finish. Therefore, those methods are often only used for size or dimensional testing. Stereolithography, however, lets manufacturers build finer finishes into their complex-geometry print designs, minimizing post-processing steps.

Other 3D-printing methods produce variations in their layers that result in rough or rutted surfaces, but stereolithography has isotropy, or uniformity, between its layers due to how new layers bond to the cured layers. This uniformity results in minimal variation between layers, making SLA one of the few single-state additive production processes, resulting in less post-manufacture cleaning or polishing.

Stereolithography 3D printers can use multiple resin tanks, which means manufacturers can print objects with different colors or slightly different materials in one pass. This can create a toy that’s ready for play or print areas of varying flexibility in a single structure.

MX3D

Amsterdam’s 670-year-old canal got a modern facelift when Dutch manufacturing consultancy MX3D printed a 12-meter footbridge in one continuous piece, a project company founders described as a proof of concept and a commercial enterprise. Sensors affixed to the bridge report real-time data, introducing a new generation to additive manufacturing.

Gate Precast

Molds for concrete panels are traditionally built using wood, which restricts the size of the panel to the size a carpenter can create manually. See how a precast architectural concrete provider used 3D printing to create an eye-catching design using concrete molds to update a Brooklyn landmark.

Image courtesy of Gate Precast

AI Spacefactory

A Boston construction consultancy set out to design a system using 3D printing to build habitats on celestial bodies like the moon or Mars using on-site materials. AI Spacefactory’s model of using locally sourced materials could also translate to reducing dependence on energy-intensive materials when building dwellings on Earth.

Image courtest of Plomp & AI SpaceFactory

Autodesk digital design workflows integrate seamlessly with Formlabs’ technology to ease the journey into the world of additive manufacturing.

This Autodesk University session shows how 3D printing is revolutionizing entertainment, with filmmakers, prop shops, and production designers using it to rapidly prototype props and create production-quality versions.

Fusion 360 users can already enable 3D printing of a digital design, and this tutorial explains how to export a Fusion 360 file to an STL/mesh file, the format used on a 3D-printing device.

Stereolithography is a form of 3D printing. It’s the photochemical process in which a beam of UV light selectively cures an area of liquid resin, hardening it into polymers. In the modern additive-manufacturing era, stereolithography describes both the 3D-printing process and device that uses it.

Stereolithography is used to create 3D-printed objects in smaller consumer or prosumer 3D-printing devices, usually with polymer (plastic).

A laser or projector generates a beam of light that is aimed at an area of thermoplastic resin, curing it into a harder, polymer-based form. This makes it uniquely suited to creating small, unique objects made of polymers (rubber or plastic).

SLA is used interchangeably with stereolithography, which is the method of shining a focused beam of light on a thermoplastic resin to cure it to a state of hardness.

Although SLS (selective laser sintering), another additive-manufacturing technology, builds material up one layer at a time like stereolithography/SLA, the raw material in SLS comes in the form of a powdered polymer. A high-powered laser then fuses powder particles together on the print surface, gradually building up the structure.

SLA/stereolithography resin comes in a tank or bottle in liquid form. PLA, or polylactic acid, is a raw 3D-printing material that comes in a spool of solid plastic thread or filament.

The outcomes from SLA resin can be brittle compared to PLA, which is often slightly softer and more flexible. It’s stronger per unit of mass than SLA resin but is not suited to complex or detailed designs.