& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

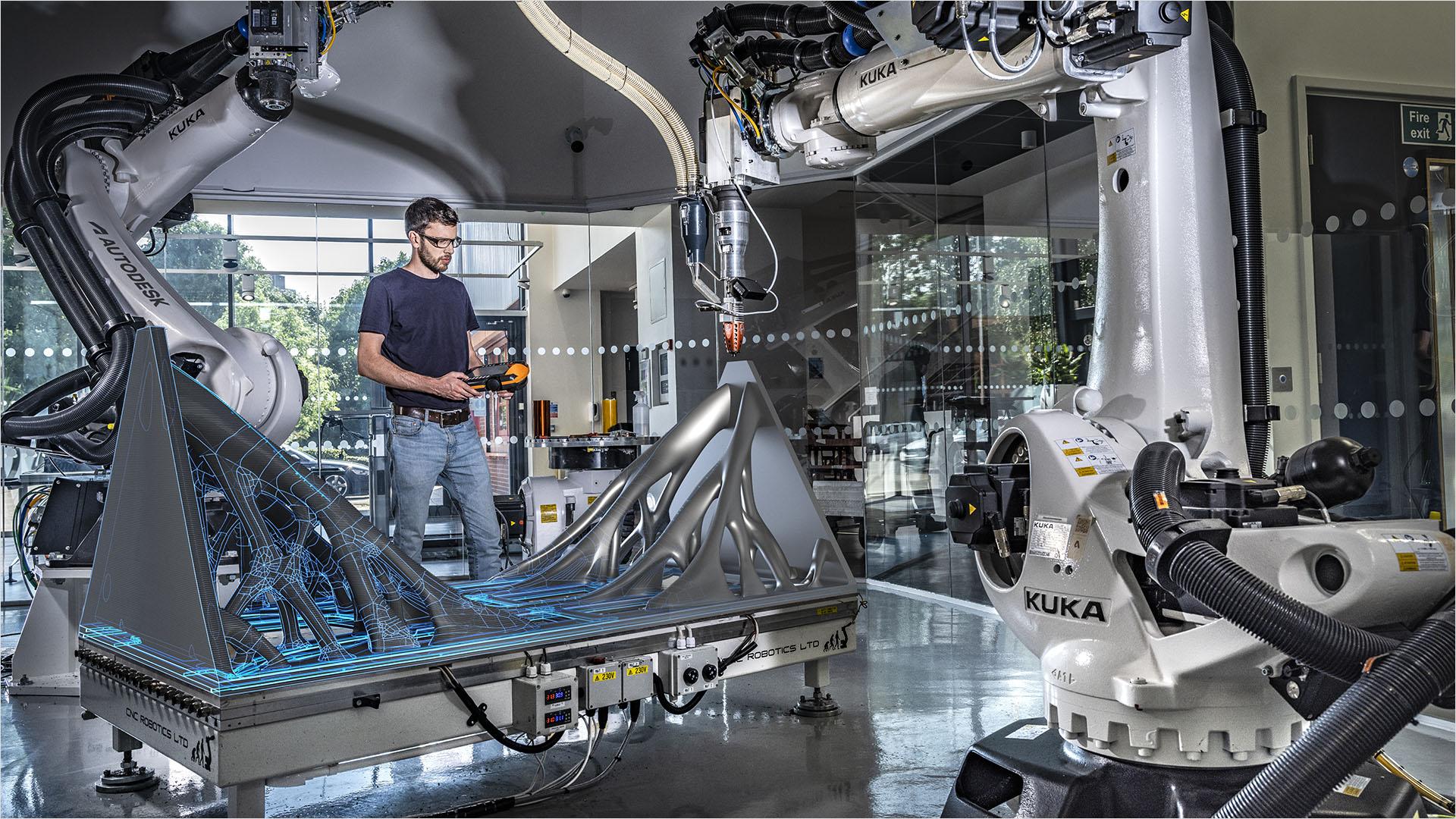

The Technology Centers provide a tangible platform that connects the digital to the physical for Autodesk Research, external teams and industry. We de-risk the future through digital design & simulation, fabrication, validation and education. The organizations and teams who engage with our facilities conduct speculative and industry-applied work to positively impact the future of design and make.

Our workshop facilities provide fabrication equipment, assembly space, and related expertise to research and development projects conducted by our internal Autodesk Research and product teams and external customer and Residency Program teams. The Technology Centers create opportunities for cross-industry collaboration and learning for Autodesk and residents.

Located in Boston’s Seaport Innovation District, the Autodesk Technology Center in Boston provides access to large-format fabrication equipment, a wide range of robotics, a composites lab, polymer and metal additive workshops, and project space to accommodate building scale construction projects.

The Autodesk Technology Center in San Francisco is located on the Embarcadero and has a wide range of advanced manufacturing equipment, robotics, hybrid metal additive, and workspaces to explore new ideas around traditional manufacturing.

The Autodesk Technology Centre in Toronto supports internal Autodesk Research projects and offers access to advanced prototyping and validation tools, collaborative robotics, metal and polymer additive, and metrology grade scanning.

The Autodesk Technology Centre in Birmingham, United Kingdom engages with customers across industries to help them develop new manufacturing and fabrication techniques. Birmingham also works closely with product teams to validate and optimize design and make workflows.

The technology centers maintain a diverse equipment portfolio that supports a range of fabrication technologies.

The Autodesk Research Residency Program is a global community of resident teams from industry, academic, and entrepreneurial sectors who are passionate about accelerating and researching design and make processes. The residency program offers open access to fabrication resources and expertise that enable teams to discover and test advanced techniques for design and make.

With new technology, job shops have unique opportunities to optimize their operations and stay competitive.

Research into design and make enables Autodesk to gain key insight into customer requirements for automation.

Adam Allard and Dr. D’Wayne Edwards discuss shoe design and manufacturing as a catalyst for change.