& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

FlexSim is easy-to-use 3D discrete event simulation software with high-end capability.

Drag-and-drop workflows to easily model production and people movement processes.

Built-in scenario manager to run experiments, make accurate predictions, and optimize.

Pre-packaged with modules to add conveyor systems, automated guided vehicles (AGVs), warehousing systems, supply chain, healthcare, and more.

FlexSim overview video (1:30 min.)

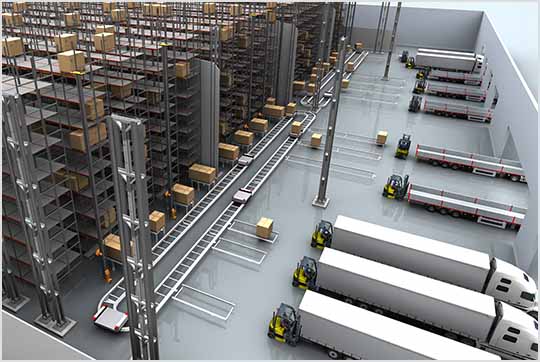

An automatic storage system, rendered in FlexSim’s RTX mode.

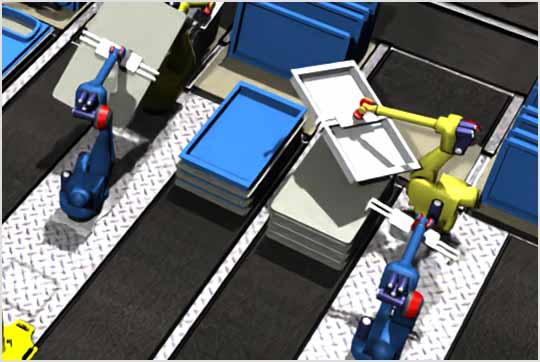

A door painting system with automated material handling.

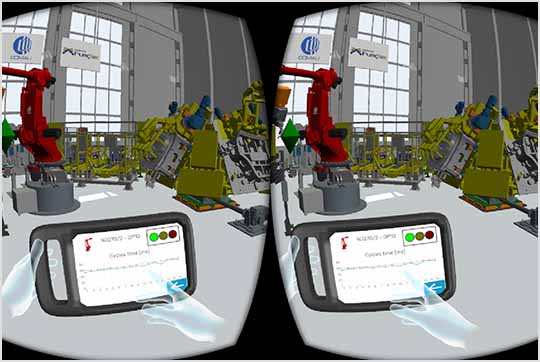

An automotive assembly line, viewed through a VR headset.

A warehouse model featuring conveyors and racks.

A dashboard with a variety of built-in charts and graphs.

A data-driven, evidence-based method to predict how changes will impact production

Test “what if” scenarios in a digital model without disrupting real-world operations

Realistic 3D visuals and process steps to share the factory story with stakeholders

DOCUMENTATION

Full documentation and reference for FlexSim, including tutorials, release notes, and more.

Q&A

FlexSim’s Q&A knowledge base and support site, with a vast database of simulation knowledge.

FlexSim is used to model production, logistics, and people movement processes, and use that model to visualize, analyze, and optimize the system. FlexSim users could be designing a new factory layout, or they could be responding to a bottleneck on the production floor, or they could be validating a reconfiguration plan to predict its impact on future operations.

FlexSim users are typically focused on process improvement and often work in an industrial engineering or manufacturing engineering role. Anyone who wants to better understand or improve production, logistics, and people movement processes can benefit from FlexSim—including project managers, analysts, quality assurance, operations, health systems engineers, Lean/Six Sigma Black Belts, and more.

At its core, a digital twin is a virtual representation of a physical process. FlexSim’s core competency is creating 3D models that represent the look and behavior of your existing system, and these models simulate how the actual system would respond using different inputs and layouts. For advanced digital twin solutions, FlexSim can pull in data at regular (or even real-time) intervals and run simulations.