& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Did you know: throughout the product development process, a huge amount of data is generated and more than 80% of that data goes untouched. So, how do you use data more efficiently? Hear from our President and CEO, Andrew Anagnost, as he shares Autodesk’s vision for empowering you to do more with your data today and in the future.

Feel ready to navigate unforeseen changes

Say digital transformation has improved productivity

Consider digital maturity a top attractor of talent

Feel AI will enhance their industry

Autodesk, 2024 State of Design & Make report and study data

D&M leaders and experts are optimistic about the global landscape, as well as their companies’ resilience, preparedness, performance, investment, and level of digital transformation. See what else they said—and how leading companies are navigating change—in our exclusive free report.

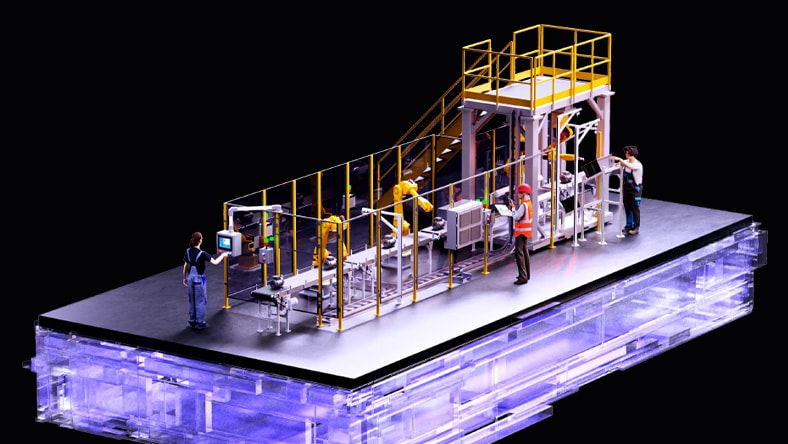

Leading manufacturers are unlocking data—to gain deeper insights, make faster decisions, and increase the pace of innovation within their organizations.

As collaboration increases, modern manufacturers must leverage new data- and technology-powered processes that better respond to evolving customer expectations.

Successful organizations will overcome skills shortages by complementing workers’ expertise with automation, artificial intelligence (AI), and generative design.

Evolving consumer tastes and new legislation is transforming sustainability from an optional case for efficient use of resources to a mandatory evolution of operations.

Artificial intelligence is becoming a crucial partner in design and manufacturing organizations by enhancing innovation and boosting productivity. While human creativity remains essential, many business leaders see AI as vital for future success.

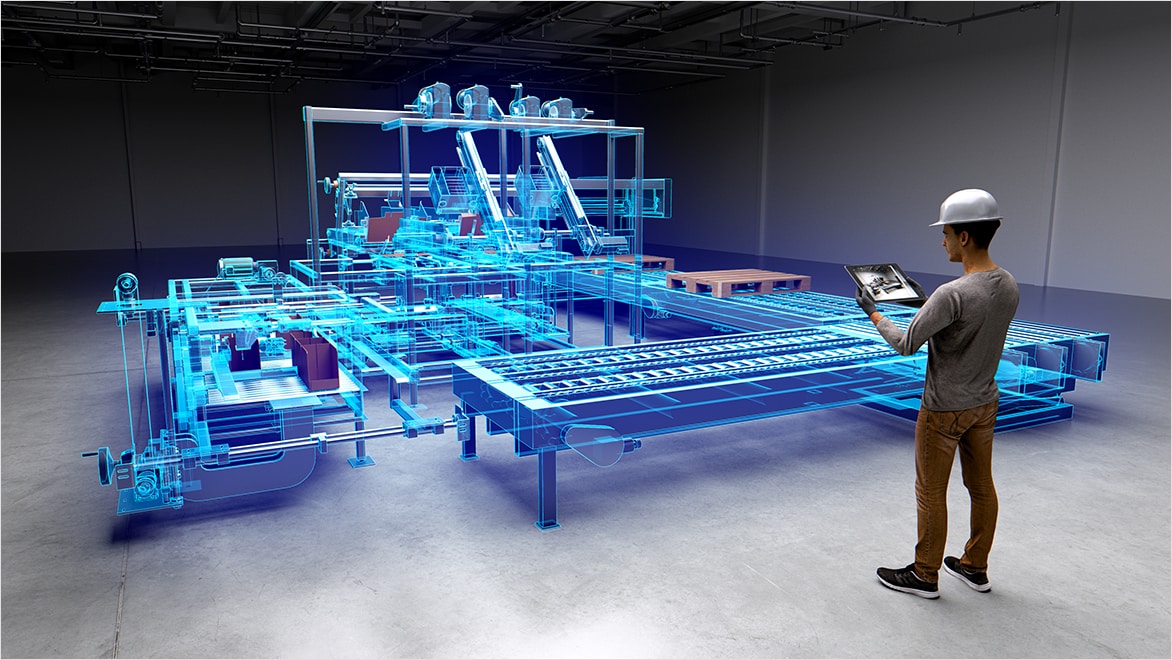

Modern manufacturing is about data, not documents. Collaboration, not silos. More open and integrated systems. The Autodesk Platform can help you embrace this future with a cloud-first evolution in design and manufacturing software—where technology connects your data, and AI-powered insights and automation unleash your agility and creativity.

Connect capabilities, data, people, and processes across your entire product development lifecycle. With Autodesk Fusion industry cloud, you can eliminate repetitive tasks and processes, accelerate productivity, and provide critical real-time insights about product development and business operations.

From generative design to automated modeling, toolpaths, and drawings, the AI built into our toolsets works alongside you to enhance creativity and decision-making. With Autodesk AI, your team can find new solutions to challenges more quickly and sustainably than ever before.

Built for designers of complex products, equipment, and systems, the Product Design & Manufacturing Collection is an integrated set of professional-grade CAD, CAM, and CAE applications, including Autodesk Inventor, AutoCAD, and Vault, with exclusive extended capabilities for simulation, visualization, reality capture, and automation.

Bring your products to market with unprecedented levels of efficiency and collaboration.

Uncover new opportunities for continuous improvement, from planning to building to operating.

Drive innovation more quickly and effectively with agile studio tools built for automotive design.

STATE OF DESIGN & MAKE REPORT

Learn how senior manufacturing executives are tackling the biggest challenges in industrial machinery.

STATE OF DESIGN & MAKE REPORT

From electrification to autonomous driving, explore how peers pursue innovation with new technologies.

ARTICLE

From Industry 4.0 to developments in AI, see how smart manufacturing is poised to transform the industry.

ON-DEMAND EVENT

Hear what Autodesk manufacturing industry leaders say about embracing this transformative new era.

As the state of the design and manufacturing industry changes around us, you don’t see a crush of discouraging obstacles—you see a world of exciting new possibilities. Contact us to discuss the ways Autodesk design and manufacturing solutions can help you explore new possibilities on your journey to solving the world’s most interesting problems.

A product is an item manufactured to benefit your customers. Your services can also be referred to as your product. Nowadays, many "smart" products merge physical items with internet-connected digital services, which offer ongoing value to the customer beyond the physical item's value.

Product design is the process of imagining, creating, and iterating on solutions that solve problems for customers in commercial sectors like industrial machinery or automotive manufacturing or directly for the public in sectors such as consumer products.

The product design process begins with research to understand the market and customer needs. Designers use knowledge, empathy, and creativity to conceptualize solutions.

Hand sketches, prototypes, technical drawings, and 3D computer-aided designs (CAD) models are created to communicate and review the proposed product design solution and to coordinate the design process among stakeholders. Further prototyping is used to test and validate concept designs with real customers.

The final output is a product requirements document, specification, technical drawing, and visuals. Typically, product designers work with design engineers to develop concept designs ready for manufacturing.

Jobs in product design could include design manager, industrial designer, product designer, UI/UX designer, graphic designer, animation designer, design engineer, technical designer, design drafter, CAD designer, CAD technician, and CAD operator.

Manufacturing is the process of converting raw materials or components into finished products through various techniques, tools, and machinery. It involves a series of steps, including designing, planning, sourcing materials, assembling, testing, and packaging.

Manufacturing is carried out in many industries; examples include Industrial machinery, automotive, building products, consumer products, and electronics. The goal of manufacturing is to create products that meet specific quality standards, are cost-effective, and can be delivered to customers in a timely manner.

Jobs in manufacturing could include production worker/operator, quality control inspector, manufacturing engineer, industrial engineer, CAD/CAM engineer, CAM programmer, CNC machinist/setter/operator, fabricator, supply chain manager, maintenance technician, logistics coordinator, CAD designer, CAD technician, and CAD operator.

Product design and manufacturing form a closely linked and iterative process that turns a conceptual design into a real product in the hands of your customer.

Desirability, manufacturability, cost, and efficiency need to be considered during the design phase to ensure that the product can be manufactured successfully while meeting the desired price point and customers' quality expectations. In return, feedback from the manufacturing process informs design improvements and optimizations.

Overall, product design and manufacturing work together to create products that are visually appealing, functional, and feasible to produce efficiently and cost-effectively.

Product design plays a crucial role in the manufacturing process for the following reasons:

Product design is important in the manufacturing process because it ensures that products meet customer needs, can be efficiently manufactured, are of the desired quality, and offer a competitive advantage in the market. Design engineering is a critical step in manufacturing successful and profitable products.

Autodesk empowers innovators with design and make technology for product design and manufacturing, equipping customers to work fluidly across boundaries of project, discipline, and industry.

Autodesk software for design and engineering:

Autodesk provides a range of software tools specifically designed to support designers and engineers. Each tool is tailored to a specific discipline and offers a range of features and capabilities to support the design and engineering process, including 2D and 3D CAD modeling, automatic BOM creation, manufacturing documentation, and engineering simulation (CAE).

3D rendering and animation software for design visualization.

Autodesk software for manufacturing::

Autodesk offers a range of computer-aided manufacturing (CAM) software solutions. These tools enable manufacturers to generate toolpaths, simulate machining operations, and optimize CNC programs for milling, turning, and other machining processes.

The company that brings you AutoCAD, Autodesk offers a range of cross-compatible design and engineering tools for 2D and 3D design. You don’t have to choose between 2D and 3D CAD. In many cases, the best option is a combination of both.

Autodesk Inventor ‘AnyCAD’ allows 2D AutoCAD data to be referenced into a 3D Inventor model. The AutoCAD data can remain the single source of truth, and the Inventor model will update when the AutoCAD model updates.

Autodesk Inventor uses the same DWG file format as AutoCAD. Inventor drawings can be opened in AutoCAD for processing including review and markup.

Autodesk Vault product data management (PDM) manages 2D and 3D data seamlessly, supporting your needs to work with legacy 2D data, migrate from 2D to 3D, or use 2D and 3D design tools concurrently.

AutoCAD, Autodesk Inventor, and Vault are available in the Product Design & Manufacturing Collection.

Computer-aided design (CAD) software offers several benefits that enhance the product design and manufacturing process:

Overall, CAD software enhances product design and manufacturing by improving visualization, accuracy, collaboration, optimization, and documentation. It helps create better designs, reducing errors, shortening development cycles, and ultimately delivering higher-quality products to the market efficiently.